Introduction

Materials and Methods

Plant materials

Storage Conditions and Packaging Containers

Assessment of Fruit Quality Attributes

Statistical Analyses

Results

Fruit Appearance Relative to Packaging Container under a Simulated Distribution System

Fruit Quality Attributes during Shelf Life

Physiological Disorders and Mechanical Damage during Shelf Life

Fruit Quality Attributes during Shelf Life after Cold Storage

Physiological Disorders and Mechanical Damage during Shelf Life after Cold Storage

Correlation Among Fruit Quality Attributes and Injury

Discussion

Introduction

Immediately after harvest, hardy kiwifruit [Actinidia arguta (Sieb. et Zucc.) Planch. ex Miq.] can undergo direct processing for sorting and packing into specific volumes of packaging containers for commercial handling and marketing. Alternatively, harvested fruit could be stored at low temperatures in wholesale or retail markets to provide a consistent supply based on consumer demand. Unfortunately, the fruit of hardy kiwifruit can be exposed to the risk of physiological disorders, physical injury, and mechanical damage during processing or handling and during the wholesale/retail distribution period (Clark et al., 2004; Kim et al., 2020; Gwanpua et al., 2022). The fruit quality of hardy kiwifruit based on fruit maturity remains inconsistent, depending on the hardy kiwifruit cultivars at harvest (Latocha et al., 2011; Kim et al., 2014; Park et al., 2022) and when the fruit are in cold storage (Fisk et al., 2006a, 2006b). Thus, various postharvest physiological disorders and types of physical damage could develop and become aggravated during cold storage and handling periods. In other words, fruit shriveling, peel pitting, and fruit decay could develop after harvest and during cold storage, reducing the overall fruit quality and marketability (Han et al., 2019; Kim et al., 2020). Following cold storage, numerous physiological disorders are typically associated with chilling injury (Zhang et al., 2021). Mechanical forms of damage such as fruit bruising and wounding, referred to as physical injuries, could also develop, resulting in the deterioration of fruit quality. In addition, fruit quality attributes can fluctuate during cold storage and shelf life, causing fruit quality and marketability levels to decline sharply during the shelf life (Han et al., 2019).

Although fruit quality attributes are diverse mainly depending on the hardy kiwifruit cultivar (Kim et al., 2012), certain fruit quality attributes, including the soluble solids content (SSC), flesh firmness, and titratable acidity (TA), could be highly affected during cold storage (Krupa et al., 2011). During cold storage, SSC and fruit weight loss gradually increase; however, TA and flesh firmness inversely respond in ‘Skinny Green’ baby kiwifruit (Oh et al., 2017). In general, hardy kiwifruit sorted based on fruit size and fresh weight can be conventionally stored and packed in a clamshell-type plastic container with a lid and then distributed to wholesale and retail markets in Korea. The packaging containers of hardy kiwifruit cannot perfectly absorb all possible vibrations or mechanical shocks generated during handling and transport. In addition, fruit can be exposed to unfavorable conditions that can induce physiological disorders and physical damage or injuries, resulting in the deterioration of both the fruit quality and appearance and thereby contributing to a decline in marketability. Along with the alteration of physiological and biochemical fruit quality attributes, physiological disorders and physical damage such as fruit bruising, fruit wounding, peel browning, and fruit shriveling develop and become severely aggravated with an increase in the handling period in the market. The hardy kiwifruit were packed into low-vent containers, which can hold a small amount of fruit in individual wells, indicating considerable suppression of the fruit weight loss during storage and shelf life, compared to high-vent containers (Fisk et al., 2008). Furthermore, several studies have been conducted to evaluate packaging materials to reduce bruise damage in kiwifruit (Xia et al., 2020) and retain fruit quality during cold storage for red raspberries (Giovanelli et al., 2014) and cucumber (Owoyemi et al., 2021). Hammock-type and elastic film packages have been developed and used in the strawberry industry. Consequently, individual strawberries do not require contact with adjacent fruits or trays, thereby preventing mechanical damage and physical injuries during long-term distribution and marketing (Hikawa-Endo, 2020). Various packaging materials, such as high-density polyethylene (HDPE) bags, low-density polyethylene (LDPE) bags, dried banana leaf, and teff straw, were also applied to three banana cultivars to evaluate their effects on extending the shelf life of bananas (Hailu et al., 2014). In addition, the most appropriate packaging material for extending the shelf life of pear fruit were reported to be non-perforated polypropylene among various plastic packaging materials (Nath et al., 2012). The current packaging type of hardy kiwifruit, which is a clamshell-type plastic container, cannot sufficiently prevent mechanical damage and is completely unable to maintain premium fruit quality during the traditional handling period. Therefore, this study aimed to evaluate the effects of different packaging containers on extending the shelf-life of hardy kiwifruit, specifically the physiological and biochemical fruit quality attributes, physical damage, and physiological disorders, in two contrasting hardy kiwifruit cultivars. The assessment was based on the fruit size and fresh weight for 7 d of shelf life at 22°C and 3 d of shelf life after cold storage at 10°C for 7 d, simulating conditions representative of the commercial handling and distribution system.

Materials and Methods

Plant materials

The fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit [Actinidia arguta (Sieb. et Zucc.) Planch. ex Miq.] cultivars were harvested on September 4 and 18, 2023, respectively, after reaching practical and commercial mature stages at local hardy kiwifruit orchards (37° 27’ 7”, 127° 53’ 18”) in Wonju, Kangwon-do, Republic of Korea. The fruit were transferred to a laboratory within 2 h and randomly divided into five groups of five different packaging containers. The average fruit sizes of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars at harvest were as follows: fruit fresh weight (g), 19.8 ± 2.1 and 34.0 ± 4.5; fruit long diameter (mm), 31.9 ± 0.3 and 38.5 ± 0.5; fruit short diameter (mm), 27.0 ± 0.2 and 31.8 ± 0.4; and fruit length (mm), 38.4 ± 0.3 and 41.6 ± 0.7, respectively. The experimental fruits were selected considering their uniform size and lack of defects. Fifteen fruits of ‘Autumn Sense’ (SSC: 6.0%, Firmness: 9.0 N) and ‘Daebo’ (SSC: 6.1%, Firmness: 9.0 N) hardy kiwifruit (five fruits per replicate) were used as experimental materials.

Storage Conditions and Packaging Containers

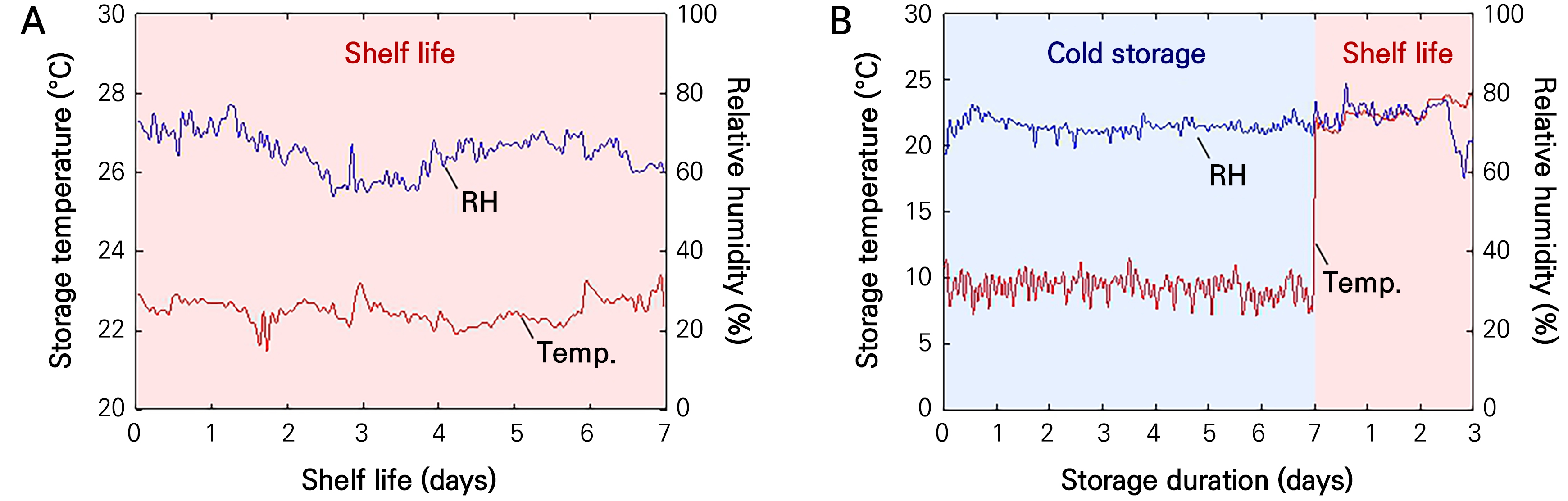

The hardy kiwifruit packed into each container were stored under two storage regimes: 1) 7 d of shelf life at 22°C for the evaluation of the shelf-life effect and 2) 3 d of shelf life at 22°C after 7 d of cold storage at 10°C for the evaluation of the cold storage effect. Storage temperatures and relative humidity (RH) levels during the shelf life and cold storage periods were periodically recorded using a data logger (TR-72wf, T&D Co., Nagano, Japan) (Fig. 1). During the shelf life, the storage temperature fluctuated at approximately 22°C and the relative humidity (RH) remained between 55% and 80% (Fig. 1A). In contrast, under the distribution system, the storage temperature remained at approximately 10°C and then increased sharply to 22°C for 3 d of shelf life. Nonetheless, RH remained stable between 60% and 80%, regardless of the cold storage and shelf-life period (Fig. 1B).

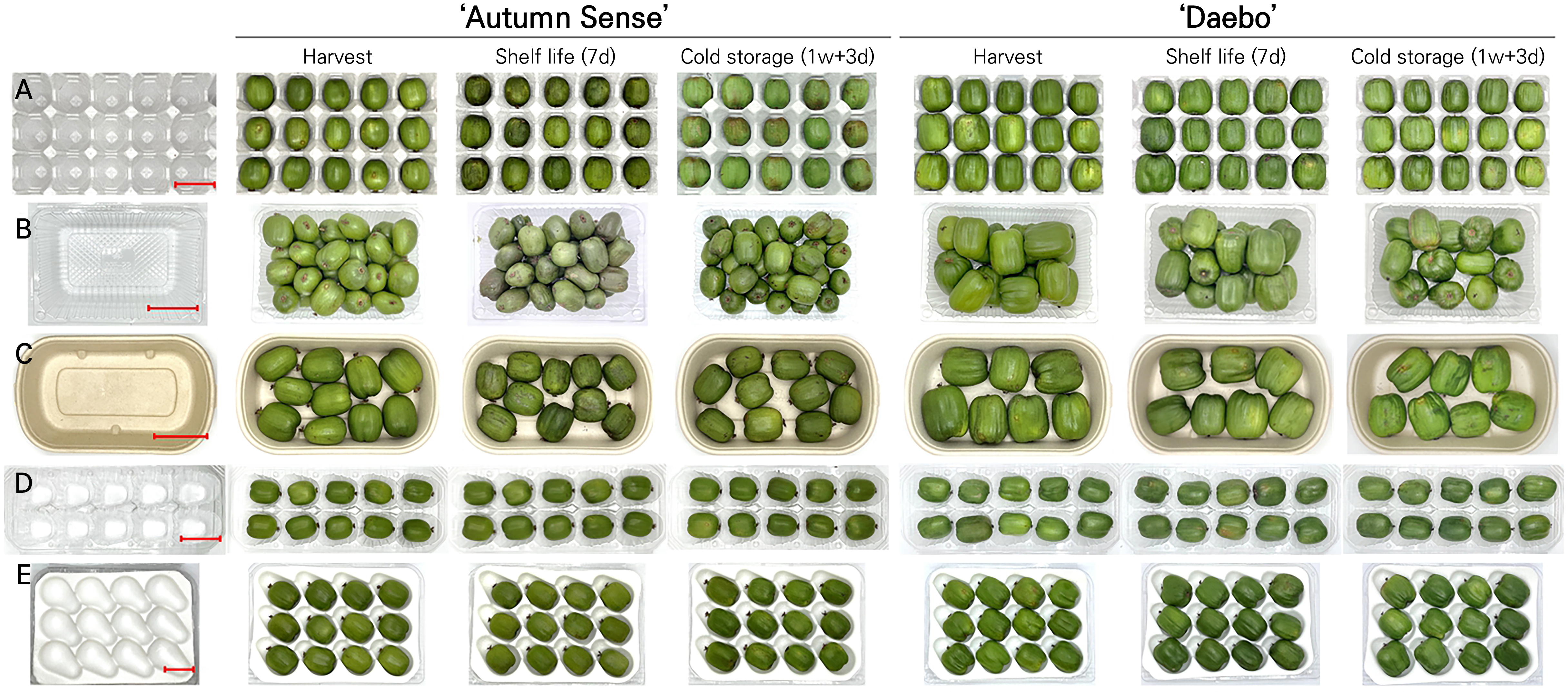

Each cultivar was packed into five different packaging containers. The size and a description of each packaging container are as follows: A) pressed pulp egg tray (300 × 300 × 55 mm): compressed pulp egg tray comprising molded recycled newspaper (Einston Co., Cheongju, Republic of Korea); B) clamshell container (185 × 130 × 70 mm, SB-304B, Starpack Co., Incheon, Republic of Korea): a one-piece vented container made of polyethylene terephthalate (PET) comprising two halves joined by a hinge that allows the halves to close together; C) pressed pulp container (195 × 115 × 35 mm, Nanu Co., Ansan, Republic of Korea): a rectangular container with rounded corners made from sugarcane bagasse, with a lid of the same material; D) 10-cavity container (115 × 285 × 60 mm, I-895, Ipack P&D Co., LTD, Yongin, Republic of Korea): a one-piece non-perforated clamshell container made of molded PET; E) 12-cavity container with polyolefin foam (225 × 165 × 45 mm, S-208R, Sinwontech Inc., Nonsan, Republic of Korea): a one-piece vented clamshell container made of molded PET containing polyolefin foam as a cushioning material (Fig. 2).

Fig. 2.

Packaging container effect on the visual appearance of the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars at harvest, after 7 d of shelf life at 22°C and after 3 d of shelf life at 22°C after 7 d of cold storage at 10°C. A: pressed pulp egg tray; B: clamshell container; C: pressed pulp container; D: 10-cavity container; and E: 12-cavity with polyolefin container. The red scale bars indicate 5 cm.

Assessment of Fruit Quality Attributes

The various physiological and biochemical attributes of hardy kiwifruit were evaluated as follows. Fruit fresh weight was recorded at harvest and after storage to calculate the fruit weight loss, which was determined as the difference in weight between harvest and after storage. The peel color variables of lightness (L*), chroma (C*), hue angle (h°), redness (a*), and yellowness (b*) were measured twice on the equator region of individual fruit using a chromameter (CR-300, Minolta Co., Tokyo, Japan) (McGuire, 1992; Byeon et al., 2023; Latt et al., 2023).

Fruit firmness was measured using a texture analyzer (CT3, AMETEK Brookfield, Inc., Middleborough, MA, USA) equipped with a 2-mm plunger on opposite sides of unpeeled fruit, and the results were expressed in Newtons (N). Fresh-squeezed hardy kiwifruit juice was used to determine the SSC and TA using a digital refractometer (PAL-1, Atago Co., Tokyo, Japan) and an automatic titration system (EasyPlus Titrator, Mettler-Toledo, LLC, Columbus, OH, USA) with 0.1 M NaOH titrated to an endpoint of pH 8.2. Both results are expressed as percentages, and TA is expressed as a percentage of anhydrous citric acid, the dominant organic acid in hardy kiwifruit (Fisk et al., 2008).

The fruit respiration rate and ethylene production level were measured as follows: 1 mL gas samples were collected from five fruit placed in airtight plastic containers (0.92 L) after 2 h of incubation. The collected gas samples were injected into a gas chromatograph (YL6500GC, YL Instrument Co., Ltd., Anyang, Republic of Korea) activated by an 80/100 Porapak Q column (Supelco Inc., Supelco Park, Bellefonte, PA, USA) to detect CO2. The injector, thermal conductivity detector, and oven temperatures were set to 200, 150, and 50°C, respectively (Lwin et al., 2022). Ethylene production was measured using a gas chromatograph (Agilent 8890 GC, Agilent Technologies Inc., Santa Clara, CA, USA) equipped with a CP-Al2O3 / Na2SO4 column (50 m × 0.53 mm i.d. × 10 µm film thickness, Agilent Technologies Inc., Santa Clara, CA, USA). The injector, flame ionization detector, and oven temperatures were set to 200, 250, and 70°C, respectively (Byeon et al., 2023).

The incidence of physiological disorders and mechanical damage, in this case bruising, wounding, softening, shriveling, peel browning, and total spoilage, were evaluated at 7 d of shelf life and 3 d of shelf life after 7 d of cold storage. The incidence rate (%) of all disorders and damage was expressed as the percentage of affected fruit relative to the total number of fruit tested (Byeon et al., 2023; Lwin et al., 2023).

Statistical Analyses

A completely randomized design was applied to evaluate the packaging container effects on the fruit quality, physiological disorders, and mechanical damage (or injuries) in the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars during shelf life and cold storage. All results are presented as the mean ± standard error (SE) of the mean. An analysis of variance (ANOVA), in which the packaging container and hardy kiwifruit cultivar were considered the main factors, was used to determine the statistical significance of all variables. The significance of the mean difference was analyzed using the least significant difference (LSD) test (p < 0.05) using SAS version 9.3 (SAS Institute Inc., Cary, NC, USA). Correlation coefficients were calculated based on Pearson correlation coefficient test using MetaboAnalyst 5.0 (Pang et al., 2021). Based on the results of the correlation coefficient test, a correlation coefficient network was generated using the MetScape (version 3.1.3) plugin for Cytoscape (version 3.10.0; https://cytoscape.org/), depending on the packaging container, hardy kiwifruit cultivar, and storage regime (Shannon et al., 2003; Lwin and Lee, 2022).

Results

Fruit Appearance Relative to Packaging Container under a Simulated Distribution System

Five types of packaging containers were used: pressed pulp egg trays (Fig. 2A), clamshell containers with a lid (Fig. 2B), pressed pulp containers with a lid (Fig. 2C), non-perforated 10-cavity containers with a lid (Fig. 2D), and 12-cavity containers with polyolefin foam with ventilation (Fig. 2E). Overall, fruit appearance was better in the cavity container type than in the pressed pulp and clamshell containers. In addition, the responses differed slightly depending on the fruit type of the hardy kiwifruit cultivar. Moreover, the fruit quality of the ‘Daebo’ cultivar was markedly better than that of the ‘Autumn Sense’ cultivar, regardless of the storage regime (Fig. 2).

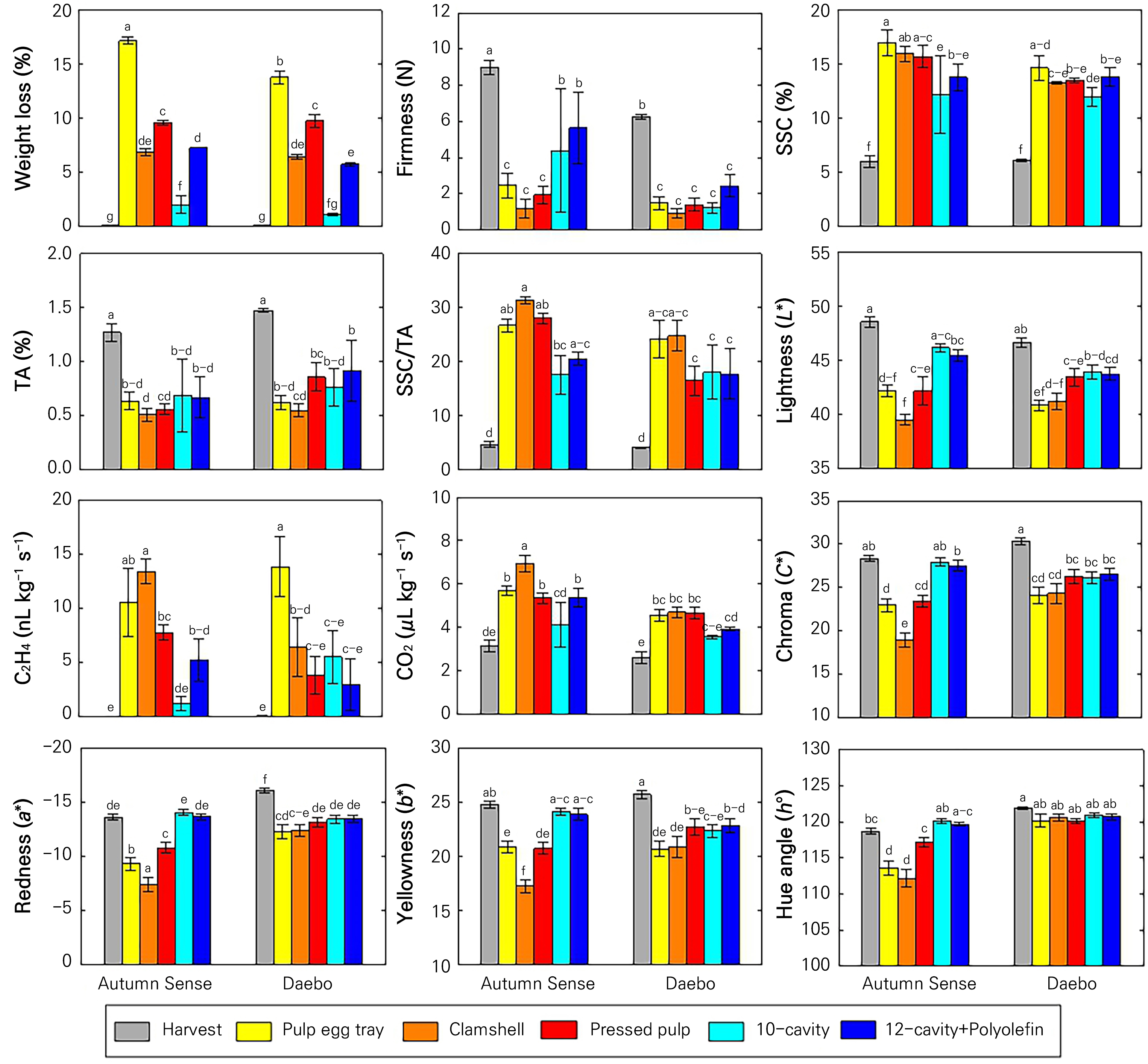

Fruit Quality Attributes during Shelf Life

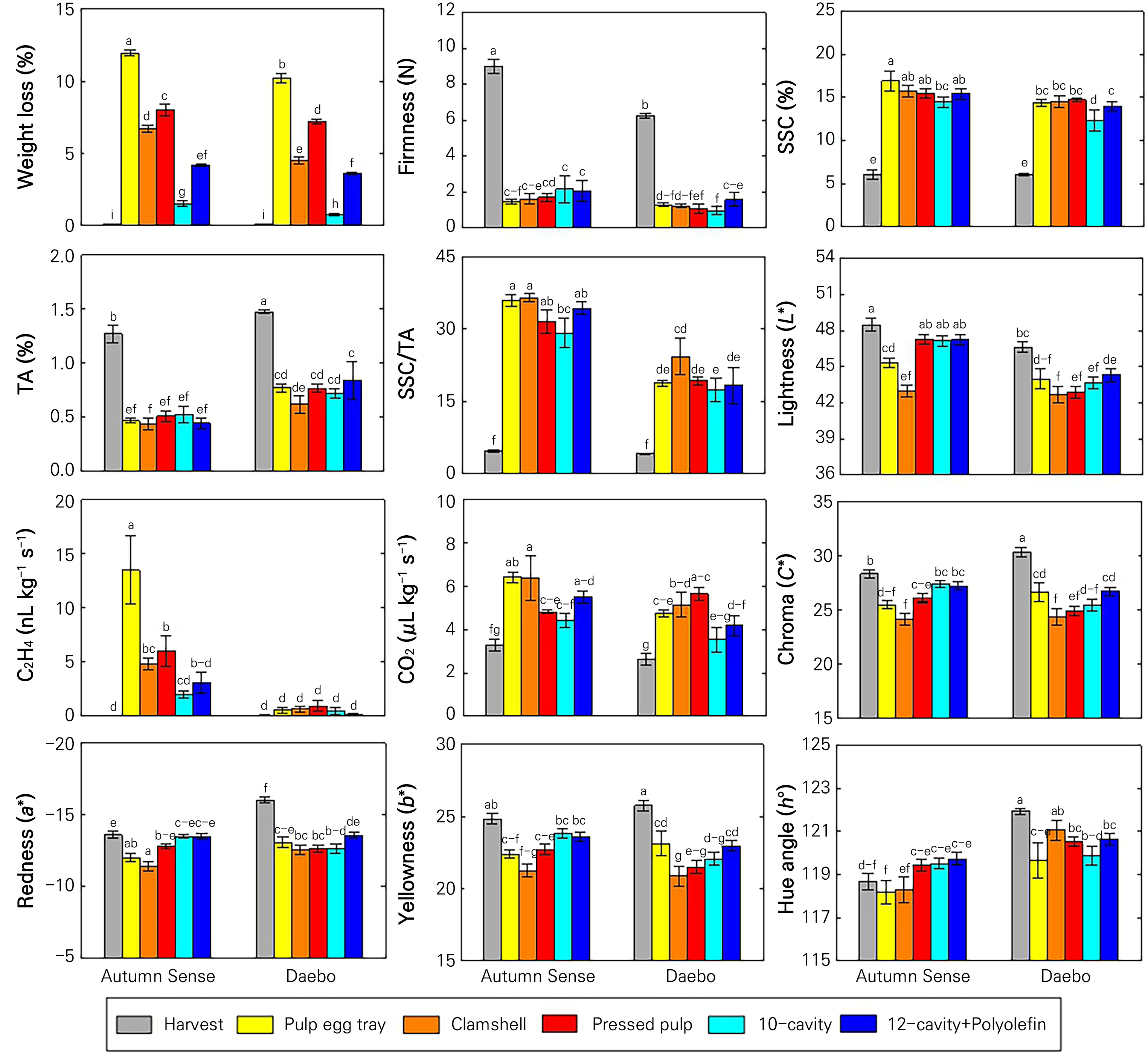

During shelf life, the fruit weight loss was highest in the pressed pulp egg tray without a lid but lowest in the 10-cavity container, regardless of the hardy kiwifruit cultivar. Flesh firmness was highest at harvest but declined sharply during shelf life in both cultivars, irrespective of the packaging container; firmness was considerably higher in the cavity containers than in the clamshell and pressed pulp containers with a lid in the ‘Autumn Sense’ cultivar but did not differ in the ‘Daebo’ cultivar. In addition, there was considerable variation in the flesh firmness in the cavity containers of the ‘Autumn Sense’ cultivar. This indicated that the fruit maturity of the ‘Autumn Sense’ hardy kiwifruit was inconsistent during its shelf life. The SSC levels were greatly increased during shelf life, compared with those at harvest. Although no significant difference was detected in the SSC of the ‘Daebo’ cultivar, the SSC was higher in the pressed pulp egg tray, clamshell container, and pressed pulp container compared to cavity-type containers in the ‘Autumn Sense’ cultivar. In contrast, TA was greatly reduced after 7 d of shelf life, regardless of the packaging container and hardy kiwifruit cultivar. Nevertheless, the SSC/TA ratio tended to be higher in the ‘Autumn Sense’ cultivar than in the ‘Daebo’ cultivar, with higher values in the pressed pulp egg trays and clamshell containers than in the cavity-type containers. The ethylene production rate was highest in the clamshell container but lowest in the 10-cavity container for the ‘Autumn Sense’ cultivar. However, the ethylene production rate was highest in the pressed pulp egg tray but lowest in the other four packaging containers for the ‘Daebo’ cultivar. The fruit respiration rate increased during shelf life, irrespective of the hardy kiwifruit cultivar and packaging container, except for the 10-cavity container. Fruit respiration was highest in the clamshell container but lowest in the 10-cavity container for both cultivars. Peel color variables, specifically the peel lightness, peel chroma, peel hue angle, peel redness, and peel yellowness, were lowest in the clamshell container, compared to the other container types in the ‘Autumn Sense’ cultivar. However, no significant differences were detected among the packaging containers for the ‘Daebo’ cultivar. Overall physiological and biochemical responses indicated that the hardy kiwifruit packed in clamshell and pressed pulp container ripened rapidly after 7 d of shelf life, while the 10-cavity and 12-cavity with polyolefin foam containers maintained fruit quality in the ‘Autumn Sense’ cultivar (Fig. 3).

Fig. 3.

Physiological and biochemical responses of the fresh fruit weight loss, ethylene production rate, respiration rate, flesh firmness, soluble solids content (SSC), titratable acidity (TA), SSC/TA ratio, peel lightness (L*), peel chroma (C*), peel hue angle (h°), peel redness (a*), and peel yellowness (b*) in the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars after 7 d of shelf life at 22°C. Each data bar indicates the mean ± standard error (SE) of three replicates (n = 3) with five fruit per replicate. Different letters above the bars indicate significant differences according to the least significant difference (LSD) test at p < 0.05.

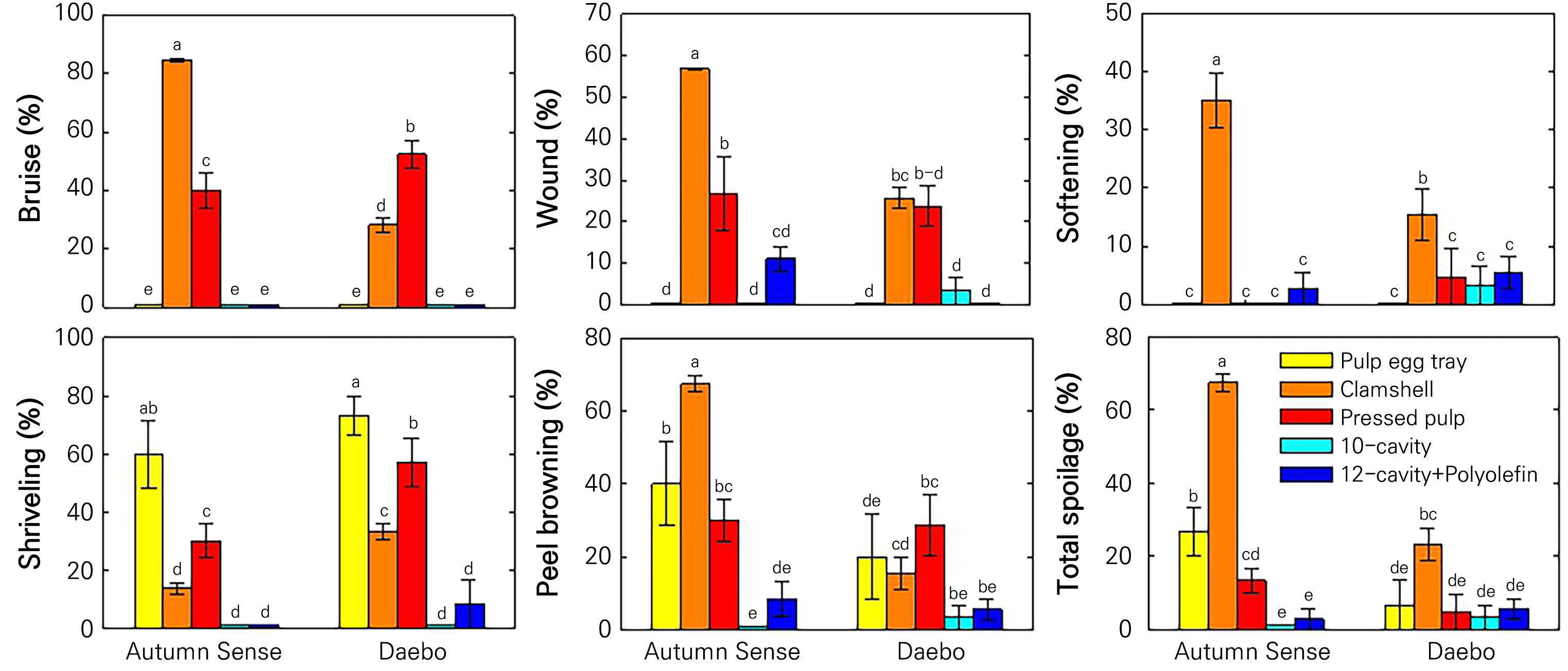

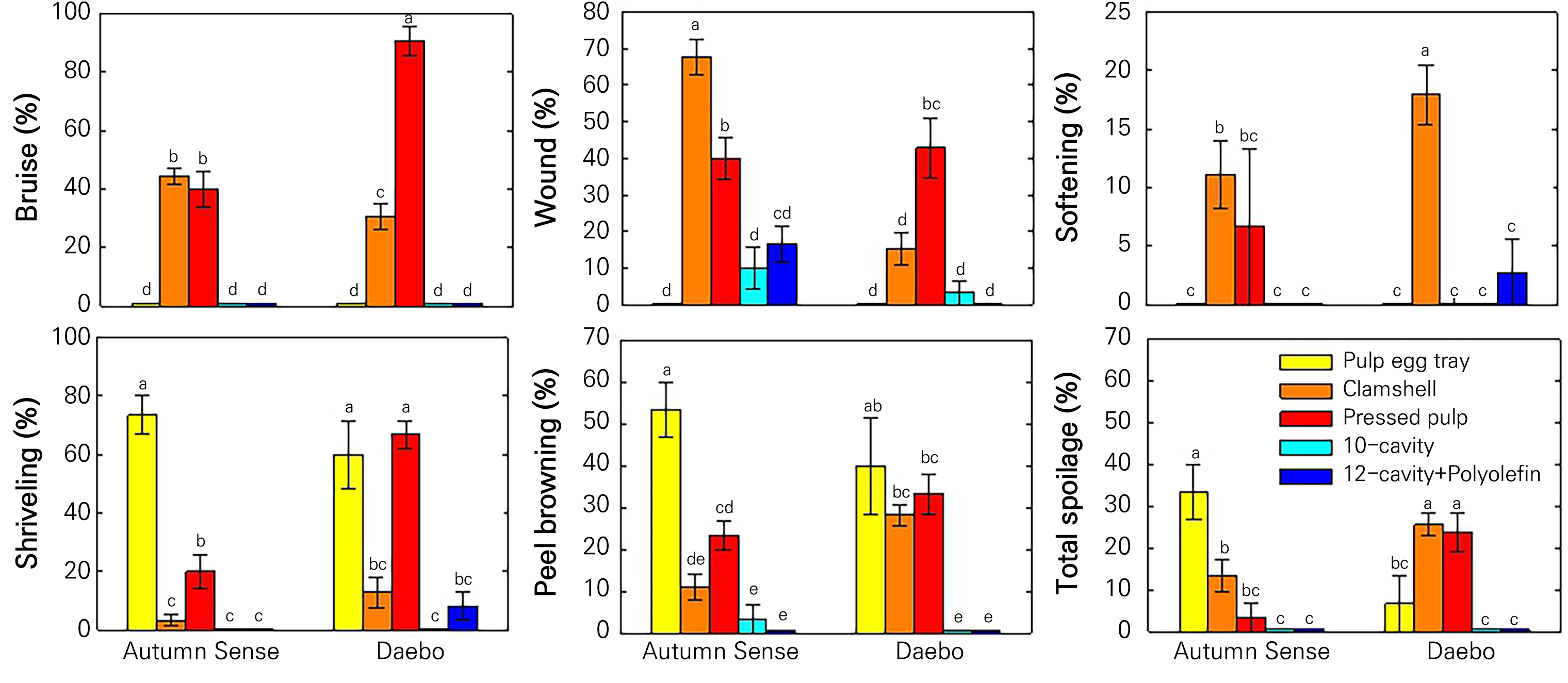

Physiological Disorders and Mechanical Damage during Shelf Life

The fruit bruise rate was highest in the clamshell container for the ‘Autumn Sense’ cultivar but was highest in the pressed pulp container for the ‘Daebo’ cultivar during shelf life. No bruising symptoms were observed in the cavity containers. Fruit wounding was also highest in the clamshell container for the ‘Autumn Sense’ cultivar, compared to the other packaging containers but was still lower in the cavity containers for both cultivars. Fruit softening was highest in the clamshell container for both cultivars but negligible in the other packaging containers for both cultivars. Fruit shriveling was highest in the pressed pulp egg tray for both cultivars because the pressed pulp egg tray had no lid to cover the fruit compared to the other packaging containers. In turn, fruit shriveling was higher in the pressed pulp container in both cultivars than in the other packaging containers. These results were derived from the pressed pulp, which may help to remove water molecules from the fruit during shelf life, as shown in a pressed pulp egg tray made from paper fiber or pulp. Meanwhile, peel browning was very severe in the clamshell and pressed pulp containers, compared to the cavity-type containers in the ‘Autumn Sense’ cultivar. However, peel browning in the ‘Daebo’ cultivar was highest in the pressed pulp container, compared with the other packaging containers. Moreover, overall fruit spoilage during shelf life was higher in the ‘Autumn Sense’ cultivar than in the ‘Daebo’ cultivar. Overall, total fruit spoilage was highest in the clamshell containers for both cultivars compared to the other packaging containers (Fig. 4).

Fig. 4.

Incidence of bruise, wound, softening, shriveling, peel browning, and total spoilage in the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars after 7 d of shelf life at 22°C. Each data bar is the mean ± standard error (SE) of three replicates (n = 3) per packaging container. Different letters above the bars indicate significant differences according to the least significant difference (LSD) test at p < 0.05.

Fruit Quality Attributes during Shelf Life after Cold Storage

Fruit weight loss was highest in the pressed pulp egg trays for both cultivars but lowest in the 10-cavity containers, compared to the other packaging containers. However, flesh firmness declined substantially during shelf life after cold storage but was not statistically different among the packaging containers in both cultivars. In turn, SSC increased sharply during shelf life after cold storage. SSC was highest in the pressed pulp egg tray but lowest in the 10-cavity container, compared to the other containers for the ‘Autumn Sense’ cultivar. For the ‘Daebo’ cultivar, the 10-cavity container had the lowest SSC, compared to the other containers. TA declined significantly during shelf life after cold storage, compared to that at harvest. TA was not statistically different among the packaging containers for either cultivar. Nonetheless, the overall TA level was higher in the ‘Daebo’ cultivar than in the ‘Autumn Sense’ cultivar. Therefore, the SSC/TA ratio was higher in the ‘Autumn Sense’ cultivar than in the ‘Daebo’ cultivar. The SSC/TA ratio was highest in the clamshell container but lowest in the 10-cavity container for both cultivars. Interestingly, ethylene production was highest in the pressed pulp egg tray but lowest in the 10-cavity container, compared to the other containers for the ‘Autumn Sense’ cultivar. However, negligible level of ethylene was produced in the ‘Daebo’ cultivar, irrespective of the packaging container used. The fruit respiration rate increased during shelf life after cold storage, compared to that at harvest. The fruit respiration rate was highest in the clamshell container but lowest in the 10-cavity container for both cultivars. Peel color variables, specifically the peel lightness, peel chroma, peel hue angle, peel redness, and peel yellowness, were lowest in the clamshell container but highest in the cavity containers in both cultivars; however, peel hue angle values were inconsistent for the ‘Daebo’ cultivar. These results demonstrate that fruit ripening was more affected by the packaging container in the ‘Autumn Sense’ cultivar than in the ‘Daebo’ cultivar during cold storage (Fig. 5).

Fig. 5.

Physiological and biochemical responses of the fresh fruit weight loss, ethylene production rate, respiration rate, flesh firmness, soluble solids content (SSC), titratable acidity (TA), SSC/TA ratio, peel lightness (L*), peel chroma (C*), peel hue angle (h°), peel redness (a*), and peel yellowness (b*) in the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars after 3 d of shelf life at 22°C after 7 d of cold storage at 10°C. Each data bar is the mean ± standard error (SE) of three replicates (n = 3) with five fruit per replicate. Different letters above the bars indicate significant differences according to the least significant difference (LSD) test at p < 0.05.

Physiological Disorders and Mechanical Damage during Shelf Life after Cold Storage

The fruit bruise rate was highest in the clamshell and pressed pulp containers for both cultivars but was negligible in the other containers. In addition, the fruit wounding rate was highest in the clamshell containers for the ‘Autumn Sense’ cultivar and highest in the pressed pulp containers for the ‘Daebo’ cultivar, with negligible symptoms of fruit wounding found in the cavity containers. Fruit softening was highest in the clamshell and pressed pulp containers for the ‘Autumn Sense’ cultivar but only highest in the clamshell container for the ‘Daebo’ cultivar. However, negligible fruit softening was detected in the cavity containers for both cultivars. In addition, fruit shriveling was highest in the pressed pulp egg trays for both cultivars, compared to the other containers but was lowest in the cavity containers. Peel browning was also highest in the pressed pulp egg trays for both cultivars, compared with the other containers. Although peel browning was negligible in the cavity containers, it was detected at a high rate in the clamshell and pressed pulp containers for both cultivars. Overall, total fruit spoilage was highest in the pressed pulp egg trays for the ‘Autumn Sense’ cultivar and was higher in the clamshell and pressed pulp containers for the ‘Daebo’ cultivar, compared to the other types (Fig. 6).

Fig. 6.

Incidence of bruise, wound, softening, shriveling, peel browning, and total spoilage in the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars after 3 d of shelf life at 22°C after 7 d of cold storage at 10°C. Each data bar is the mean ± standard error (SE) of three replicates (n = 3) per packaging container. Different letters above the bars indicate significant differences according to the least significant difference (LSD) test at p < 0.05.

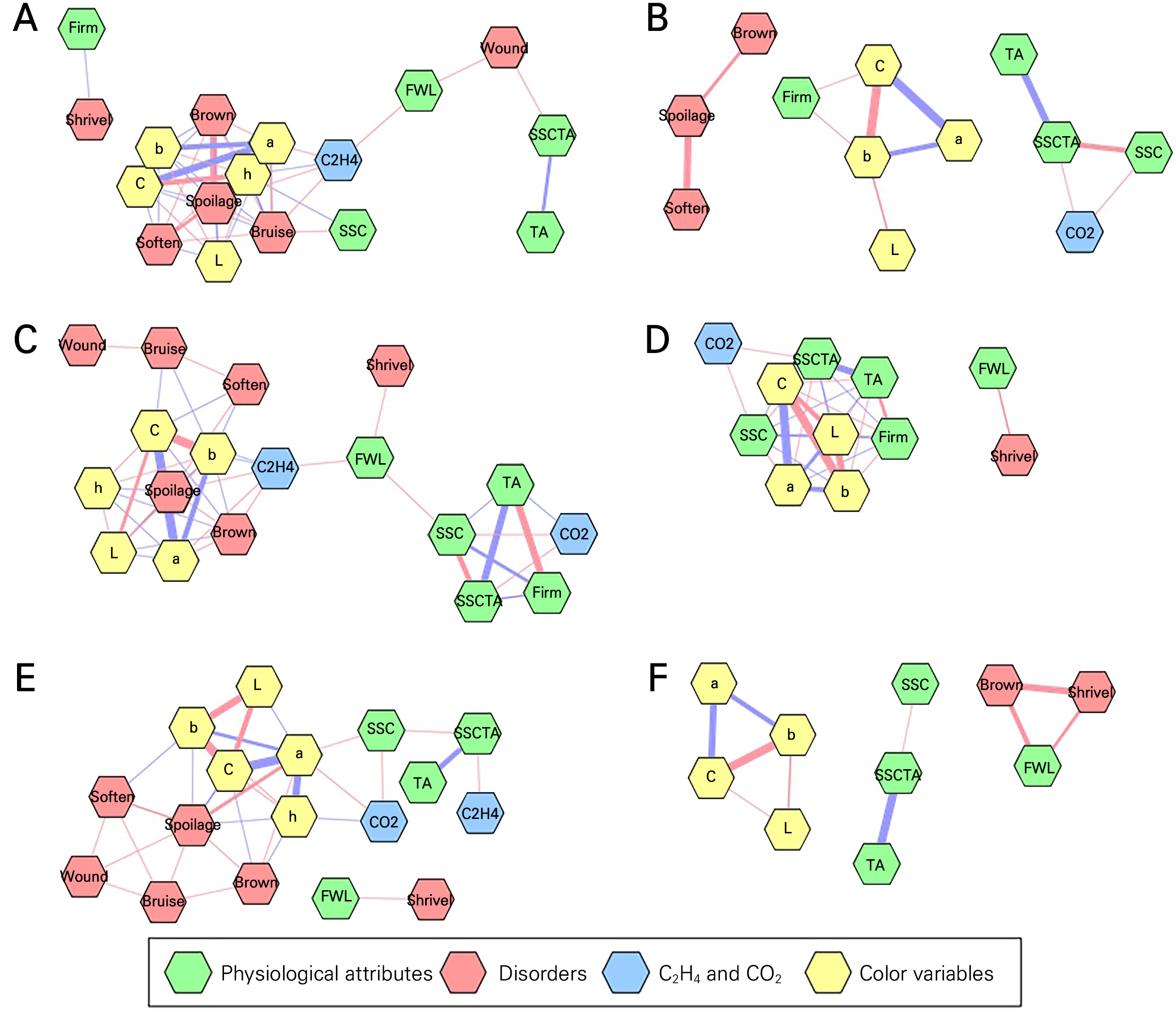

Correlation Among Fruit Quality Attributes and Injury

Among the packaging containers, the clamshell container had the highest incidences of fruit bruising, wounding, and softening, whereas the 10-cavity container had the lowest incidences of fruit shriveling, peel browning, and fruit spoilage. Based on the results of the fruit quality attributes, Pearson correlation coefficient network system was applied for the overall evaluation of the fruit quality attributes depending on the corresponding packaging container and hardy kiwifruit cultivar (Fig. 7). In the clamshell container, which has been conventionally applied for hardy kiwifruit marketing, peel browning, fruit total spoilage, softening, and bruises were closely correlated with peel color variables, along with SSC and ethylene production, which were positively correlated with the fruit weight loss. Fruit wounding was positively correlated with FWL and SSC/TA and negatively correlated with TA. Fruit shriveling was negatively correlated with flesh firmness (Fig. 7A). However, peel browning, fruit spoilage, and fruit softening were positively correlated in the 10-cavity container where the fruit were mostly sealed (or under less ventilation). Flesh firmness was positively correlated with peel chroma and yellowness and negatively correlated with peel redness. SSC/TA was positively correlated with SSC and the fruit respiration rate but negatively correlated with TA (Fig. 7B).

In contrast, in the ‘Autumn Sense’ cultivar, fruit wounding, fruit bruising, fruit softening, fruit total spoilage and peel browning were closely correlated with peel color variables, along with ethylene production, which was positively correlated with FWL. FWL was positively correlated with fruit shriveling and SSC, which was highly correlated with TA, fruit respiration, flesh firmness, and the SSC/TA ratio (Fig. 7C). In the ‘Daebo’ cultivar, peel color variables were highly correlated with SSC, the SSC/TA ratio, TA, and flesh firmness. Simultaneously, fruit respiration was positively correlated with SSC and the SSC/TA ratio. Fruit shriveling was positively correlated with FWL (Fig. 7D).

Regarding the storage regimes, during shelf life immediately after harvest, physiological disorders and mechanical damage were positively correlated with each other, excluding fruit shriveling. Fruit softening, total spoilage, and peel browning were negatively correlated with peel color variables, but not peel redness; however, peel color variables were highly correlated with themselves. Peel redness was negatively correlated with the other color variables but positively correlated with fruit respiration and SSC, which were positively correlated with SSC/TA. SSC/TA was negatively correlated with TA but positively correlated with ethylene production. Fruit weight loss was positively correlated with shriveling (Fig. 7E). In contrast, during shelf life after cold storage, peel redness (a*) was negatively correlated with peel chroma and peel yellowness (b*), which were positively correlated with peel lightness. SSC/TA ratio was positively correlated with SSC but negatively correlated with TA. Fruit weight loss was positively correlated with peel browning and shriveling (Fig. 7F).

Fig. 7.

Pearson correlation coefficient (r ≥ |0.70|) network among physiological fruit quality attributes, physiological disorders, and mechanical damage in the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars after 7 d of shelf life at 22°C and 3 d of shelf life at 22°C after 7 d of cold storage at 10°C. A: clamshell container; B: 10-cavity container; C: ‘Autumn Sense’ hardy kiwifruit cultivar; D: ‘Daebo’ hardy kiwifruit cultivar; E: after 7 d of shelf life at 22°C; F: after 3 d of shelf life at 22°C following 7 d of cold storage at 10°C. Red and blue lines indicate positive and negative correlations among the variables, respectively. The thickness of the correlation coefficient network lines indicates the significance of the correlation coefficient (r) between the variables. Abbreviations used in this figure are as follows: firm, firmness; FWL, fruit weight loss; soften, softening; spoilage, total spoilage; brown, peel browning; shrivel, shriveling.

Discussion

The fruit of hardy kiwifruit packed with bulk into clamshell-type plastic containers can be exposed to irrelevant conditions to retain fruit quality, inducing symptoms of postharvest physiological disorders and mechanical injuries, such as peel browning, peel pitting, shriveling, softening, bruising, wounding, and decay during the distribution process (Fernando et al., 2019). Currently, innovative packaging materials are being actively developed to maintain premium fruit quality by avoiding direct contact among the fruits and containers and minimizing physical vibrations and shocks during handling and transport (Wang et al., 2022; Chaiwong et al., 2023). Thus, this study aimed to evaluate the effects of a wide range of packaging containers covered with pressed pulp or plastic materials on fruit quality attributes, physiological disorders, and mechanical damage in the fruit of ‘Autumn Sense’ and ‘Daebo’ hardy kiwifruit cultivars after 7 d of shelf life or after 3 d of shelf life following 7 d of cold storage.

The pressed pulp egg tray was used as a positive control because it did not have a lid to cover the entire tray and was easily accessible for evaluating the fruit quality of the hardy kiwifruit. As shown in Figs. 3 and 5, the fruit weight loss was highest in the pressed pulp egg tray compared to the other containers, irrespective of the hardy kiwifruit cultivar and storage regime. In other words, the fruit packed in pressed pulp egg trays were more susceptible to rapid water molecule loss during shelf life and cold storage. It is reasonable to assume that fruit ripening, as indicated by ethylene production and respiration rates, would progress more rapidly, resulting in the highest fruit weight loss in the pressed pulp egg tray compared to the other container types. During cold storage and shelf life, retaining relevant RH levels using a plastic liner is closely associated with the incidence of physiological disorders and fruit quality in cold-stored ‘Royal Gala’ apples (Lee et al., 2019b). Clamshell containers have been broadly applied as conventional bulk packaging materials for commercial hardy kiwifruit packaging and transport (Fisk et al., 2008). Unfortunately, the clamshell container induced more severe bruising, wounding, softening, and peel browning, thereby aggravating the fruit quality in terms of the total fruit spoilage, irrespective of the hardy kiwifruit cultivar and storage regime (Figs. 4 and 6). When packed in a plastic clamshell container, fruit are placed in bulk rather than individually packed, leading to the development of several mechanical injuries and severe symptoms of mechanical damage, along with a loss of fruit quality. Thus, these disorders and mechanical damage were closely correlated with peel color variables (Fig. 7A). In contrast, negligible symptoms of physiological disorders and mechanical damage were detected in the 10-cavity container for both cultivars and storage regimes (Figs. 4 and 6). Therefore, physiological disorders and mechanical damage were not correlated with fruit quality (Fig. 7B). The fruit were sealed in a non-perforated 10-cavity container, resulting in the lowest fruit weight loss during both storage regimes in both cultivars. In addition, the reduction in ethylene production and fruit respiration rate resulted from the physical characteristics of the 10-cavity container. Therefore, the 10-cavity container may serve to delay fruit ripening, thereby contributing to the retention of fruit quality during shelf life and cold storage. In persimmon fruit, modified atmosphere packaging (MAP), referred to as an air-tightly sealed packaging material, delayed fruit softening compared to cardboard packaging during cold storage (Fahmy and Nakano, 2016). A micro-perforated MAP treatment delayed the reduction of fruit weight loss and thus retained higher pericarp firmness, resulting in the control of fruit shriveling during the shelf life of paprika cultivars (Lwin et al., 2022). Therefore, the results here indicate that the non-perforated 10-cavity plastic container, also known as a less-ventilation plastic container, could be essential in delaying the increase in fruit respiration and thus reducing the fruit weight loss, thereby contributing to extending fruit freshness during storage by suppressing fruit softening compared to a regular clamshell plastic container of the type with greater ventilation.

Between the two hardy kiwifruit cultivars, the ‘Autumn Sense’ cultivar appears to be more susceptible to incidences of physiological disorders and mechanical damage than the ‘Daebo’ cultivar during both storage regimes, although certain inconsistencies were observed (Figs. 4 and 6). According to the results of the correlation coefficient network, the incidences of physiological disorders and mechanical damage were strongly correlated with peel color variables, ethylene production, and fruit weight loss in the ‘Autumn Sense’ cultivar (Fig. 7C). However, only specific fruit quality attributes were highly correlated with themselves without physiological disorders and mechanical damage, though fruit weight loss was positively correlated with shriveling in the ‘Daebo’ cultivar (Fig. 7D). Although there were no considerable differences detected among the fruit quality attributes of the two cultivars during shelf life (Fig. 3), level of ethylene production was negligible in the ‘Daebo’ cultivar, thus retaining a higher level of TA and resulting in reduced fruit respiration, regardless of packaging containers during shelf life after cold storage. Fruit ripening patterns, in terms of respiration and ethylene production rates, are cultivar-dependent in cold-stored kiwifruit (Shin et al., 2018; Kim et al., 2023). Fruit ripening patterns are affected by kiwifruit cultivars and fruit maturity during cold storage (Tilahun et al., 2020). Therefore, the results suggest that a cold storage treatment after harvest could more clearly contribute to delaying fruit ripening by inhibiting ethylene production and fruit respiration and then suppressing the loss of TA in the ‘Daebo’ cultivar, compared to the fruit ripening responses of the ‘Autumn Sense’ cultivar.

The overall responses of the fruit quality attributes, physiological disorders, and mechanical damage were more active during shelf life than during shelf life after cold storage in both cultivars (Figs. 3, 4, 5 and 6). Thus, most disorders and damage were strongly correlated with each other and were related to peel color variables, which were correlated with other fruit quality attributes only during the shelf-life period (Fig. 7E). However, there were three correlation clusters detected in which peel color variables and specific fruit quality attributes were only correlated with themselves during shelf life after cold storage (Fig. 7F). Moreover, the results indicate that fruit quality attributes could be more affected during the shelf-life period immediately after harvest than during the shelf life after cold storage. Furthermore, the cold storage treatment reduced fruit respiration, delayed the increase in SSC, and the decrease in TA compared to that in the ambient temperature regime, regardless of the hardy kiwifruit cultivar (Kim et al., 2020). Fruit quality attributes in ‘Fuji’ apples responded considerably more actively to the shelf-life period immediately after harvest than to long-term cold storage, in which lower storage temperature would be fundamental for controlling ethylene production and fruit respiration and thus delaying fruit ripening (Lee et al., 2019a). In addition, hydro-cooling after harvest is highly effective in reducing ethylene production and retaining fruit quality in peach fruit during storage (Pervitasari et al., 2021). Therefore, the results suggest that fruit quality could be relatively more effectively retained after cold storage than during direct shelf life after harvest, contributing to better control over the incidence of physiological disorders and mechanical damage. However, there were certain variations depending on the hardy kiwifruit cultivar and packaging container used.

In conclusion, the conventional clamshell plastic container showed higher fruit weight loss and fruit respiration rates and induced more severe physiological disorders and mechanical damage in both cultivars during both storage regimes compared to the other containers tested here, except for the pressed pulp egg tray. In contrast, the 10-cavity plastic container exhibited the lowest fruit weight loss, least ethylene production, and lowest fruit respiration rate compared to the other containers during both storage regimes. Consequently, the incidence of physiological disorders and mechanical damage was lowest during both storage regimes, irrespective of the hardy kiwifruit cultivar. Therefore, the overall results suggest that the non-perforated (less-ventilated) 10-cavity plastic container is a more reasonable choice in which to pack the fruit of hardy kiwifruit, to extend the shelf life immediately after harvest, and to extend the shelf life following cold storage. Moreover, retention of fruit quality was much better during shelf life after cold storage, compared to the shelf life immediately after harvest. In addition, a cultivar-dependent effect was detected for ethylene production and fruit respiration under both storage regimes. Thus, the results indicate that the hardy kiwifruit cultivar plays a critical role in retaining fruit quality and controlling the incidence of physiological disorders and mechanical damage during its packaging and handling periods.