Introduction

Materials and Methods

Plant Materials and Orchard Layout

Thinning Treatments

Assessments of the Leaf Damage Rate, Removal of Terminal and Lateral Flowers, and Fruit Set Rate

Assessments of Fruit Quality Attributes

Statistical Analysis

Results and Discussion

Effects of Mechanical Thinning on the Leaf Damage, Flower Removal, and Fruit Set Rate

Effects of Mechanical Thinning on the Fruit Weight and Size

Effects of Mechanical Thinning on Fruit Quality Attributes

Introduction

Flower thinning is a crucial practice when managing crop load levels of apple trees, as it directly affects the yield and quality of the fruit (Link, 2000). Flower thinning in apples can be performed manually (hand thinning), chemically, and/or mechanically (Solomakhin and Blanke, 2010; Yoo et al., 2016; Yoo et al., 2019; Allen et al., 2021). However, manual thinning can increase labor costs, and chemical thinning depends on the weather and the specific cultivar type, potentially leading to inconsistent results (Chun et al., 2012). Additionally, manual and chemical flower thinning methods are still used in many apple orchards in Korea due to the lack of information about mechanical flower thinning methods (Chun et al., 2012). Therefore, the mechanical flower thinning method would be an alternative to manual and chemical thinning practices to reduce the high production costs and achieve consistent results.

The effects of mechanical flower thinning have been studied previously in relation to many apple cultivars (Solomakhin and Blanke, 2010; Hehnen et al., 2012; Kon et al., 2013; Lordan et al., 2018). These researchers reported that a mechanical thinning treatment could effectively thin apple flowers, reduce the fruit set rate on the tree, and improve the fruit quality of the remaining fruit. However, the effect of the treatment depends on many factors, including the tractor driving speed (km·h-1), spindle rotor speed (rpm), canopy shape, cultivar, and the type of machine used. Additionally, leaves and shoots in the tree may be damaged by a high rotor speed (Solomakhin and Blanke, 2010). Therefore, the tractor and rotor speed during a mechanical thinning treatment should be adjusted for specific cultivars and tree types. Additionally, the use of manual or chemical thinning after mechanical flower thinning could improve the thinning efficiency and enhance the fruit quality upon harvest (Hehnen et al., 2012; Beber et al., 2016; Lordan et al., 2018). However, no available studies report the effects of mechanical flower thinning, especially for locally cultivated Korean apple cultivars.

‘Hongro’ (‘Spur Earliblaze’ × ‘Spur Golden Delicious’) is a locally developed Korean apple cultivar (Shin et al., 1989). In Korea, ‘Hongro’ is the second most widely cultivated apple cultivar and accounts for around 16.3 % of the total apple production in the country cultivated yearly (USDA, 2021). Additionally, the production of ‘Hongro’ apples has steadily increased in recent years to meet the demand during the Chuseok holiday festival (USDA, 2021). However, ‘Hongro’ has numerous flower buds and a relatively high fruit set rate, leading to excessive crop loads in trees (Shin et al., 1989; Kim and Seo, 2007; Yoo et al., 2022), and the fruit size and quality at harvest could be reduced. Hence, appropriate thinning practices are essential for this cultivar to produce high-quality apples.

Therefore, in this study, the efficiency of mechanical flower thinning on the terminal and lateral flowers and the fruit set rate in ‘Hongro’ apple trees was evaluated. Chemical thinning was also used as a flower thinning treatment to compare the results of mechanical flower thinning treatments. Additionally, the combined effects of mechanical and chemical thinning treatments were analyzed, as was the effect of mechanical flower thinning on the fruit quality of ‘Hongro’ apples at the time of harvest.

Materials and Methods

Plant Materials and Orchard Layout

This experiment was performed in an experimental orchard at the Apple Research Institute at Gunwi, Gyeongsangbuk-do, Korea. Seven-year-old ‘Hongro’ apple trees, planted in the same experimental block and with identical soil conditions with a spacing distance of 3.0 × 1.2 m, were selected for the experimental trials. The selected experimental trees were uniform in terms of their canopy size and blossom density. The trees were well trained into a slender-spindle shape and grafted into M.9 rootstock. The experimental trials were irrigated with a drip irrigation system and managed with an integrated pest and disease management system.

Thinning Treatments

The following six thinning treatments were applied in this study: (1) manual thinning (control), (2) chemical thinning (lime sulfur), (3) low mechanical thinning (200 rpm, 4 km·h-1), (4) high mechanical thinning (300 rpm, 6 km·h-1), (5) low mechanical thinning (200 rpm, 4 km·h-1) + chemical thinning, and (6) high mechanical thinning (300 rpm, 6 km·h-1) + chemical thinning.

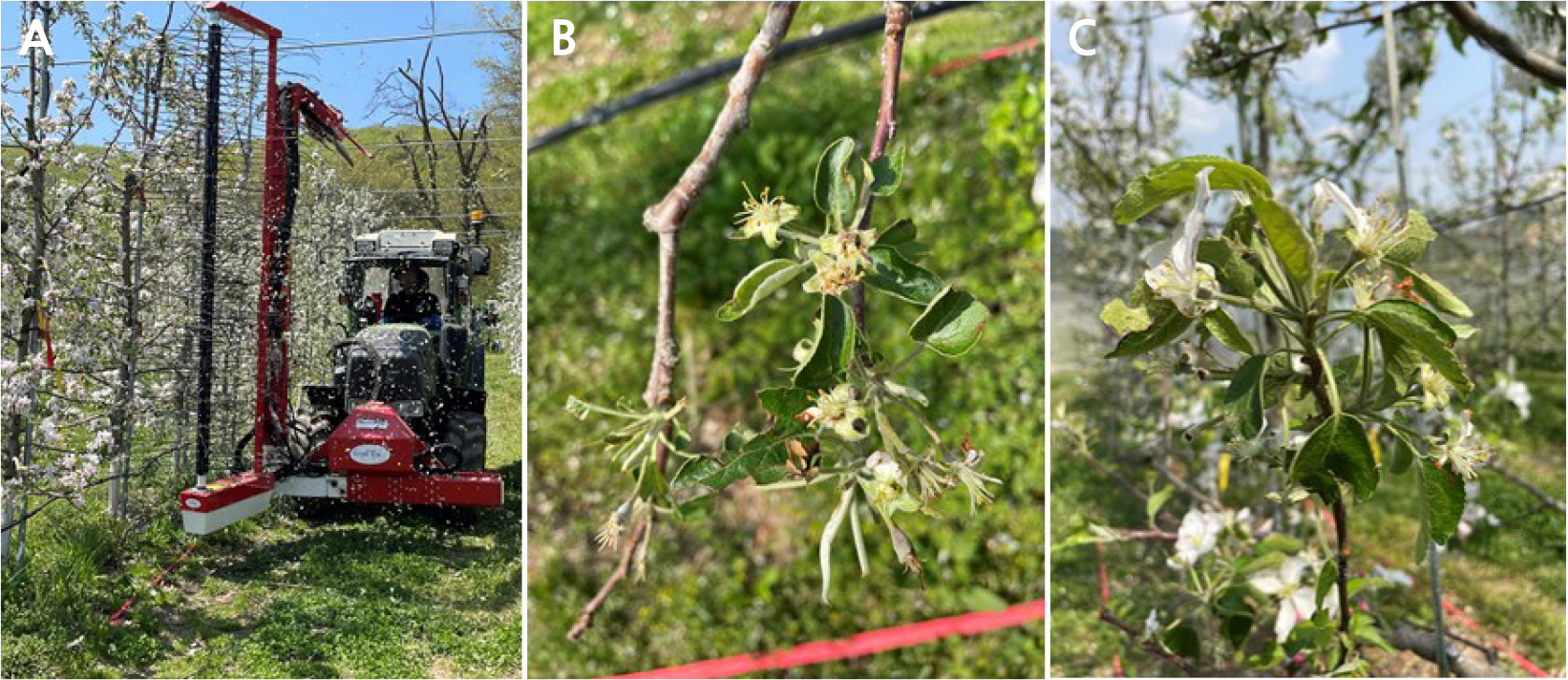

Manual thinning (control) was performed by hand. Except for the center flower (king flower), all flowers were removed in both terminal and lateral flower clusters with hand thinning. Chemical thinning was done by spraying a lime sulfur solution (120-fold dilution, 8.33 mL/L) (Be' 22, Hwangbuja, Enbio Co., Jecheon, Korea) at 20 % (April 23, 2021) and 100 % (April 25, 2021) of full bloom. The lime sulfur solution (120-fold dilution in water) was prepared according to Win et al. (2022a) and sprayed using a hand sprayer. Mechanical thinning was done at 20 % full bloom (April 23, 2021). For mechanical thinning, a Darwin S-300 (Fruit Tec Co., Markdorf, Germany) device was used as a mechanical flower thinner (Fig. 1A). For the mechanical + chemical thinning treatments, both low mechanical (200 rpm, 4 km·h-1) and high mechanical (300 rpm, 6 km·h-1) thinning treatments were done at 20 % full bloom followed by chemical thinning at 100 % full bloom. Fifteen individual trees for each treatment (total of 90 apple trees) were treated in this study.

Assessments of the Leaf Damage Rate, Removal of Terminal and Lateral Flowers, and Fruit Set Rate

Ten individual branches from different sides and locations were marked as model branches to judge the efficiency of mechanical thinning for individual apple trees and the thinning efficiency of each treatment was measured. The number of terminal and lateral flowers was counted in each flower cluster per branch before and after mechanical flower thinning. The fruit set rate was assessed in each terminal and lateral flower cluster at the end of June from the same sample branches, and the result of the fruit set rate was counted as per 100 flower clusters, following the methods of Yoo et al. (2016) and Win et al. (2022a). According to Solomakhin and Blanke (2010), the numbers of damaged leaves from the same branches were counted before and after mechanical flower thinning to measure the leaf damage rate.

Assessments of Fruit Quality Attributes

At the time of harvest, certain physiological attributes, in this case the fruit size and weight, fruit peel color, flesh firmness, starch pattern index (SPI), soluble solid content (SSC), and titratable acidity (TA), were assessed. The fruit size (diameter and length of fruit) was assessed using a digital caliper (CD-15APX, Mitutoyo Co., Japan). The fruit weight was determined using a digital scale (AND Co., Daejeon, Korea). Fruit color was measured by the CIE L* a* b* method on the red-cheek area of the fruit peel using a chroma-meter (CR-400, Konica Minolta, Japan) according to Kim et al. (2018). Fruits were peeled at three locations around the equatorial regions using a peeler to determine the flesh firmness. Flesh firmness was measured using a flesh firmness tester (11-mm probe) (FT-327, TR Co., Italy) according to Yoo et al. (2020). The SSC of a fruit juice sample in each case was determined using a refractometer (Atago Co., Japan). TA was measured by titrating the fruit juice sample with NaOH until the endpoint of pH 8.1 (Win et al., 2019). For the starch index, each apple was cut equatorially, dipped into an iodine solution, and rated using scores of 1‒8, as described by Blanpied and Silsby (1992).

Statistical Analysis

All analyses were performed using the SPSS software package (Version 25, IBM Corp., Armonk, NY, USA). Data were subjected to an analysis of variance (ANOVA), and mean comparisons were carried out using a multiple-range test (Tukey’s HSD test) to determine statistically significant differences (p < 0.05) among the treatments. All data values are expressed as the means with standard errors.

Results and Discussion

Effects of Mechanical Thinning on the Leaf Damage, Flower Removal, and Fruit Set Rate

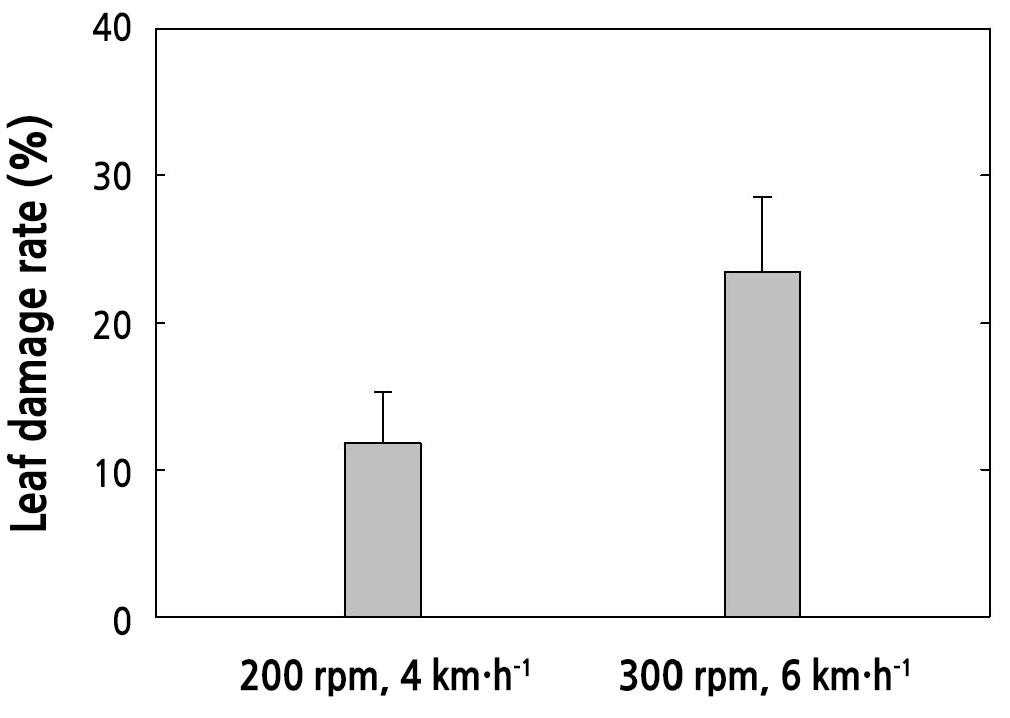

An increase in the leaf damage rate was observed at a high rotor speed (300 rpm) compared to a low rotor speed (200 rpm) (Figs. 1B, 1C, and Fig. 2). The removal of terminal and lateral flowers by the thinning treatments was measured in each flower cluster (Table 1). For the terminal flowers, the highest thinning efficiency was observed when the high mechanical + chemical thinning treatment combination was used, followed by the high mechanical thinning, chemical thinning, and low mechanical + chemical thinning treatments. The highest thinning efficiency for lateral flowers was observed with high mechanical thinning, followed by the high mechanical + chemical thinning, chemical thinning, and low mechanical + chemical thinning treatments. The lowest thinning efficiency was observed with the low rotor and tractor speed of the mechanical thinning treatment for both terminal and lateral flowers (Table 1).

For both terminal and lateral flowers, the fruit set rate was highest in manual thinning (control). At the same time, it was lowest in the high mechanical + chemical thinning treatment combination (Table 1). The fruit set rate when using the high rotor and tractor speed of mechanical thinning was significantly lower than those with the low rotor and tractor speed of mechanical thinning. However, the fruit set rate of chemical thinning was lower than that of the control but was not statistically different from those of the other thinning treatments (Table 1).

Table 1.

Effects of the mechanical thinning of flowers on the removal of terminal and lateral flowers per cluster and the fruit set rate of ‘Hongro’ apples

| Thinning treatments | Removal of flowers/cluster (no.) | Fruit set rate (%) | |||

| Terminal flowers | Lateral flowers | Terminal flowers | Lateral flowers | ||

| Hand thinning (control) | n.a. | n.a. | 77.35 ± 1.15 a | 71.15 ± 0.68 a | |

| Chemical thinning | 1.58 ± 0.27z aby | 1.24 ± 0.21 ab | 67.05 ± 3.73 bc | 60.57 ± 2.81 bc | |

| Mechanical thinning (200 rpm, 4 km·h-1) | 1.04 ± 0.10 b | 0.80 ± 0.09 b | 72.21 ± 1.27 b | 63.04 ± 2.04 b | |

| Mechanical thinning (300 rpm, 6 km·h-1) | 1.79 ± 0.08 ab | 1.64 ± 0.30 a | 66.11 ± 2.30 bc | 56.99 ± 2.05 c | |

| Mechanical (200 rpm, 4 km·h-1) + chemical thinning | 1.54 ± 0.43 ab | 0.84 ± 0.22 ab | 61.35 ± 2.48 c | 62.71 ± 0.39 b | |

| Mechanical (300 rpm, 6 km·h-1) + chemical thinning | 2.15 ± 0.29 a | 1.34 ± 0.39 ab | 59.32 ± 3.22 c | 54.24 ± 2.45 c | |

In this study, we observed that the removal of the terminal and lateral flowers increased when the rotor speed was increased. Similar findings have been observed in previous reports (Damerow et al., 2007; McClure and Cline, 2015). On the other hand, a high rotor speed increased the leaf damage rate. The reduced leaf damage rate when using low mechanical thinning (200 rpm, 4 km·h-1) was due to the low rotor speed used during this thinning method. Similarly, Solomakhin and Blanke (2010) found that a higher leaf damage rate arose at a high rotor speed as compared to a low rotor speed in ‘Gala Mondial’ apple trees.

Mechanical thinning can damage spur leaves, which are physiologically crucial for fruit growth and development (Ferree and Palmer, 1982). Additionally, Kon et al. (2013) reported that the fruit set and tree crop density could be reduced by mechanical thinning. The reduction in the fruit set rate was directly associated with a low crop load level in trees (Win et al., 2022b). In this study, the lowest fruit set rate (both terminal and lateral flowers) was observed when using the high mechanical + chemical thinning treatment. However, no difference in the fruit set rate was observed between the mechanical + chemical thinning combination and the mechanical or chemical thinning treatments (Solomakhin and Blanke, 2010). Therefore, rotor and tractor speeds should be adjusted based on the specific apple cultivar and flower density to achieve commercial crop load levels. A high rotor speed can result in flower over-thinning in trees (Kon et al., 2013; Pflanz et al., 2016).

Effects of Mechanical Thinning on the Fruit Weight and Size

A higher fruit weight was observed when using the high mechanical thinning treatment and when this treatment was combined with the chemical thinning treatment compared to the other treatments (Table 2). However, the fruit weight results were not significantly different among all thinning treatments. Similar to the fruit weight, the fruit size, including the fruit length and diameter, did not differ among all thinning treatments. However, the length and diameter (L/D) ratio of the fruit was highest with the chemical thinning treatment and lowest with the high mechanical + chemical thinning treatment (Table 2).

Table 2.

Effects of the mechanical thinning of flowers on fruit weight and size (length and diameter) of ‘Hongro’ apples

| Thinning treatments |

Fruit weight (g) | Fruit size (mm) | ||

| Length (L) | Diameter (D) | L/D ratio | ||

| Hand thinning (control) | 311.59 ± 18.42z ay | 83.11 ± 1.51 a | 92.82 ± 1.96 a | 0.90 ± 0.01 bc |

| Chemical thinning | 311.67 ± 25.12 a | 83.66 ± 2.06 a | 89.99 ± 2.47 a | 0.93 ± 0.00 a |

| Mechanical thinning (200 rpm, 4 km·h-1) | 317.08 ± 5.20 a | 81.99 ± 0.68 a | 92.40 ± 0.43 a | 0.89 ± 0.01 bc |

| Mechanical thinning (300 rpm, 6 km·h-1) | 321.59 ± 18.42 a | 83.11 ± 1.51 a | 92.82 ± 1.96 a | 0.91 ± 0.01 b |

| Mechanical (200 rpm, 4 km·h-1) + chemical thinning | 317.80 ± 16.69 a | 83.44 ± 1.13 a | 93.85 ± 0.44 a | 0.89 ± 0.01 bc |

| Mechanical (300 rpm, 6 km·h-1) + chemical thinning | 319.49 ± 10.79 a | 80.56 ± 2.41 a | 92.28 ± 1.76 a | 0.87 ± 0.02 c |

The external quality attributes of apples generally include the fruit shape, size and color along with a lack of defects (Musacchi and Serra, 2018). Improvements in the fruit weight and size are associated with the development of the fruit cell size and cell number. Larger fruits tend to have more cells per fruit, and early thinning could increase the fruit size, thereby increasing the cell number and size outcomes (Greybe et al., 1998; McClure and Cline, 2015). Additionally, an improved fruit size is also associated with the crop load level and cultivar (Serra et al., 2016; Csihon et al., 2022; Shi et al., 2022; Win et al., 2022a, 2022b). However, the increases in fruit weight and size by mechanical thinning vary depending on the specific apple cultivar and on the rotor speed used, as reported in previous studies (Solomakhin and Blanke, 2010). Fruit weights were found not to differ among different mechanical thinning treatments (180 rpm, 210 rpm, and 240 rpm) and a hand thinning treatment (McClure and Cline, 2015).

Hehnen et al. (2012) reported that mechanical thinning at a low rotor speed resulted in smaller fruits than a treatment at a high rotor speed, but the difference was nonsignificant. However, Solomakhin and Blanke (2010) found that the fruit size could vary depending on the rotor speed and apple cultivar. The fruit shape (fruit length to diameter ratio) is also essential for visual attraction by consumers, and elongated fruits may be considered less marketable (Stoper et al., 2001; Musacchi and Serra, 2018). The best result of the L/D ratio in this study was observed when chemical thinning was used, whereas the mechanical and the combination treatments resulted in a less marketable fruit shape.

Effects of Mechanical Thinning on Fruit Quality Attributes

Flesh firmness was highest with chemical thinning, followed by the high mechanical + chemical thinning and high mechanical thinning treatments (Table 3). The low mechanical treatment combined with chemical thinning did not improve the flesh firmness at the time of harvest, especially when compared to the outcomes with the high mechanical thinning and high mechanical + chemical thinning treatments. Flesh firmness by hand thinning was lower than that by chemical thinning but was not significantly different from the other thinning treatments (Table 3).

TA was highest when using the high mechanical + chemical thinning treatment at the time of harvest (Table 3). TA was also higher when using high mechanical thinning as compared to the control, low mechanical, and low mechanical + chemical thinning treatments. However, TA did not differ among the control, chemical, low mechanical, and low mechanical + chemical thinning treatments (Table 3).

SSC was higher with the mechanical + chemical combination treatments than it was in the control case (Table 3). However, SSC as well was not significantly different between the two (low and high) mechanical thinning treatments or between the two (low and high) mechanical + chemical thinning treatments. Chemical thinning had an intermediate SSC level and showed no differences in all thinning treatments (Table 3).

The a* value for the fruit peel was highest with the high mechanical thinning treatment and lowest with the chemical thinning treatment at the time of harvest (Table 3). The L* and b* values were unaffected by the thinning treatments (data not shown). Additionally, the a* values were not significantly different among the control and both mechanical thinning treatments and their combination with chemical thinning treatments (Table 3). SPI was not affected by any thinning treatment (Table 3).

Table 3.

Effects of the mechanical thinning of flowers on the flesh firmness, soluble solid content (SSC), titratable acidity (TA), fruit peel color (CIE a* value), and starch index of ‘Hongro’ apples

| Thinning treatments |

Flesh firmness (N) |

SSC (%) |

TA (%) |

Fruit peel color (CIE a* value) |

Starch index (1–8) |

| Hand thinning (control) | 59.24 ± 1.33z bcy | 12.64 ± 0.21 b | 0.23 ± 0.00 b | 15.40 ± 1.11 ab | 7.00 ± 0.27 a |

| Chemical thinning | 62.83 ± 0.36 a | 12.89 ± 0.17 ab | 0.24 ± 0.01 ab | 14.20 ± 0.16 b | 6.80 ± 0.25 a |

| Mechanical thinning (200 rpm, 4 km·h-1) | 56.93 ± 0.70 c | 13.13 ± 0.08 a | 0.23 ± 0.01 b | 16.09 ± 0.68 ab | 7.10 ± 0.19 a |

| Mechanical thinning (300 rpm, 6 km·h-1) | 60.99 ± 0.29 ab | 13.02 ± 0.26 ab | 0.26 ± 0.01 a | 17.17 ± 1.19 a | 6.90 ± 0.40 a |

| Mechanical (200 rpm, 4 km·h-1) + chemical thinning | 57.53 ± 0.79 c | 13.23 ± 0.14 a | 0.23 ± 0.01 b | 15.44 ± 0.68 ab | 6.80 ± 0.20 a |

| Mechanical (300 rpm, 6 km·h-1) + chemical thinning | 62.06 ± 1.18 ab | 13.28 ± 0.25 a | 0.27 ± 0.01 a | 16.14 ± 0.84 ab | 6.70 ± 0.25 a |

In the apple market, SSC and TA are essential quality traits for tastiness, whereas firmness is crucial for determining fruit softness (Musacchi and Serra, 2018; Valente et al., 2021; Win et al., 2021). It was reported in previous studies that mechanical thinning had a positive impact on the fruit quality of apples. In this study, flesh firmness and TA were not improved by mechanical thinning with low rotor and tractor speeds. Additionally, no further improvements in the firmness or TA were noted when the combination of low mechanical thinning and chemical thinning was used compared to hand thinning. However, firmness and TA were improved when the rotor speed was increased to 300 rpm with a 6 km·h-1 tractor speed. Moreover, optimum flesh firmness and fruit acidity were achieved by combining chemical thinning with high rotor and tractor speeds during mechanical thinning. A similar result was also reported for ‘Gala’ and ‘Elstar’ apples (Kon et al., 2013; Pflanz et al., 2016). However, some studies have reported that flesh firmness in ‘Buckeye Gala’ and ‘Gala Mondial’ apples did not improve, even when the rotor speed was increased (Solomakhin and Blanke, 2010; Hehnen et al., 2012). Similar to the firmness and TA, SSC was enhanced with the high mechanical + chemical thinning treatment. The increased SSC during the mechanical thinning of trees may be due to the reduced fruit set rate or crop load in the trees caused by thinning, leading to an increased leaf-to-fruit ratio (Kong et al., 2009). Unlike the results here, Hehnen et al. (2012) reported that the SSC in ‘Buckeye Gala’ apples was not improved by mechanical thinning or its combination with a chemical treatment. Therefore, the impact of mechanical thinning on the flesh firmness, SSC, and TA can vary according to the apple cultivar.

Fruit color, an external fruit appearance feature, is also essential for consumer choice. The development of fruit peel color, especially the a* value in red-colored apples, is directly associated with light exposure to the fruits (He and Giusti, 2010; Moon et al., 2022). Additionally, high crop loads on trees could reduce fruit color development (Robinson and Lopez, 2009). In this study, the a* value was highest after the high mechanical thinning treatment. However, the lowest a* value observed with chemical thinning was unclear in this study. SPI is generally used to estimate the harvest window or maturity of the fruit, with a high SPI value indicating starch hydrolysis in the fruit, leading to fast fruit ripening during the postharvest stage (Doerflinger et al., 2015). However, no effects of SPI have been observed in any mechanical or mechanical + chemical thinning treatments (Hehnen et al., 2012), similar to the findings here.

In conclusion, the thinning of ‘Hongro’ apple flowers by mechanical flower thinning methods positively impacted fruit quality attributes and reduced the fruit set rate in trees. However, the impact of mechanical thinning was highly dependent on the rotor speed and the tractor speed. High thinning efficiency and improved fruit quality levels were observed when using the high mechanical thinning treatment. Moreover, adding a chemical thinning after mechanical thinning improved the thinning efficiency in trees and the apple fruit quality when the fruit were harvested. It was shown in this study that a combination of high mechanical thinning with chemical thinning resulted in the best overall results with regard to the flower thinning and fruit quality of ‘Hongro’ apples.