Introduction

Materials and Methods

Plant Material and Treatments

Transportation and Distribution Conditions

Quality Evaluations

Marketability Evaluation

Results and Discussion

Changes in Temperature and RH during Transportation

Weight Loss

Incidence of Surface Browning, Decay, and Marketability

Firmness

Soluble Solids Contents

Marketability Evaluation

Introduction

Oriental melon (Cucumis melo var. makuwa Makino), also known as Korean melon, has many attractive qualities, such as a sweet and crisp taste, juicy flesh, intense aromas, and it contains a variety of sugars and vitamins, and high nutritional and medicinal values (Bai et al., 2014). Unfortunately, this melon has a short shelf-life when stored at room temperature due to its typical climacteric behavior and thin pericarp (Liu et al., 2004).

Delaying melon senescence and maintaining postharvest quality is important during storage, transport, and retail (Jin et al., 2013). The use of nitrous oxide (NO) (Singh et al., 2009), methyl jasmonate (Wang et al., 2009), chitosan (Xing et al., 2011), and modified atmosphere (MA) packaging (Amaro et al., 2012) can delay postharvest ripening and fruit senescence and maintain quality. Among the traditional postharvest treatments, MA packaging is a self-contained form of controlled atmosphere designed to maintain the internal gas composition during transportation and storage (Giuggioli et al., 2015; Huang et al., 2017). The MA extends the shelf-life of the fruit while the sealed container protects them from exposure to diseases and other environmental contaminants. Controlling the relative humidity and storage temperature are also important factors for maintaining the freshness of fruit (Choi et al., 2016a).

Recently, the export of Korean oriental melon has been expanded to Southeast Asian countries, and export via shipping containers is used to reduce transportation costs. Vessel transportation is cheaper than air transportation and can move higher volumes of produce, but it takes 3-10 days longer to transport the goods (Choi et al., 2016b). This increase in time from harvest to market presents problems when exporting oriental melon due to increased rates of decay. Therefore, better postharvest technologies for Korean oriental melon are needed, both during vessel transportation and distribution to market.

In this study, we assessed different postharvest technologies for oriental melon by monitoring changes in quality after vessel transportation, and investigated the competitiveness of Korean oriental melon through interviews with local importers in Singapore.

Materials and Methods

Plant Material and Treatments

Oriental melon (Cucumis melo var. makuwa Makino) ‘Smartkkul’ plants were grown and harvested from a commercial greenhouse in Seongju province (Gyeongsangbuk-do, South Korea). Uniform, medium-sized fruits were selected for this study.

The melons were subjected to 5 different postharvest treatments: washing with water and 5-kg bulk packaging in a corrugated box covered with polypropylene (PP) film (control), washing with water and 5-kg bulk packaging in a corrugated box covered the inside lined with polyethylene (PE) film coated with pegmatite (W+B+F), washing with water and 5-kg bulk packaging in a corrugated box with PE film and absorption paper (W+B+F+P), washing with water and small packaging, in which two oriental melons were packaged in a polyethylene terephthalate (PET) tray, and 8 trays were placed into each corrugated box (W+S), washing with 0.5% chitosan solution and small packaging (CW+S).

The water washing step was carried out with tap water for 5 min at 18±1°C and then the fruits were dried at room temperature for 3 h. For the chitosan washing treatment, the melons were washed with tap water and then dipped into 0.5% chitosan (Kitocohol, Jinro Distillers Co., Korea) solution for 5 min. After dipping, each melon was dried at room temperature for 3 h. Pegmatite, which was developed by the rural development administration (RDA), is used to maintain the quality of horticultural crops. Large and small packaging is shown in Fig. 1.

Transportation and Distribution Conditions

After treatment and packaging, oriental melons were stored for 1 day at 13°C and transported to Singapore for 9 days at 3°C by vessel container, and finally distributed for 3 days at 18°C. Temperature and relative humidity (RH) were recorded inside the container during shipping using a data logger (Watchdog B102, Spectrum Technologies Inc., Aurora, IL, USA).

Quality Evaluations

To determine the weight loss of oriental melon caused by respiration during transportation, melon fruits were weighed using a digital balance scale (HH320, OHAUS, NJ, USA) just before treatment in South Korea, and again upon their arrival in Singapore. The weight loss rate (%) was calculated using the following equation:

Weight loss rate = [(initial weight – weight after arrival in Singapore) / initial weight] × 100.

After export, the percentage of marketable melons, melons showing surface browning, and decayed fruit was recorded by dividing by the total number of melon fruit in each packaging, and multiplying by 100.

The firmness of the melon fruit was measured by a portable firmness testing device (FHM-5, Takemura, Japan). Three readings were taken on each oriental melon at two pared surfaces on the equator and recorded in kgf.

The soluble solids content (SSC) of each fruit was measured by dropping the extracted juice from the flesh and seed onto a digital refractometer (PAL-1, Atago Co. LTD, Tokyo, Japan), and SSC was expressed as °Brix.

The experiment was conducted with three replications per treatment. Analysis of variance and Duncan’s multiple range tests were performed using the SAS program (Statistical Analysis System Co. Ltd., V.9.1, Cary, NC, USA).

Marketability Evaluation

After export, we interviewed the Singapore importers on the marketability of the oriental melons in Singapore. We assessed quality, freshness, the preferences of consumers, and suggestions for improving the competitiveness of melon fruit in Singapore.

Results and Discussion

Changes in Temperature and RH during Transportation

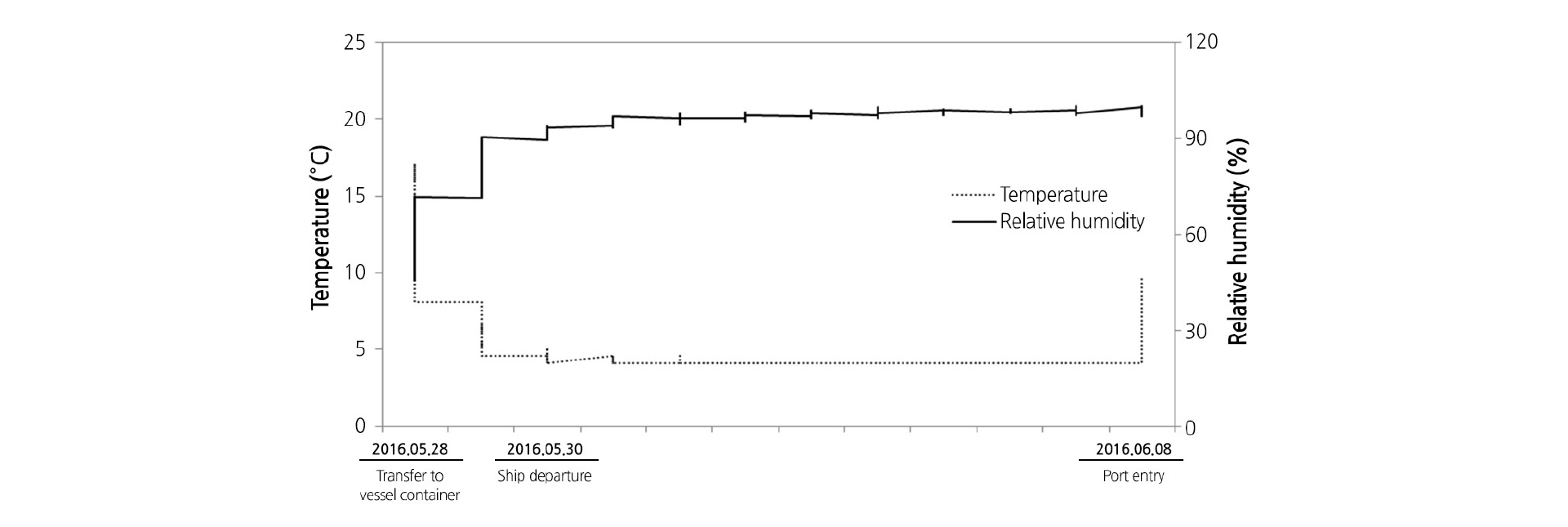

The temperature and RH inside the shipping containers are shown in Fig. 2. The temperature inside the vessel container was controlled at 3°C throughout the 9-day transportation, and the melons were distributed at 18°C after arrival in Singapore. The average range of temperature and RH were 4.1-5.3°C and 93.7-97.1%, respectively, from the beginning of departure from South Korea on 30 May, 2016 to the time of port entry in Singapore on 8 June, 2016.

Weight Loss

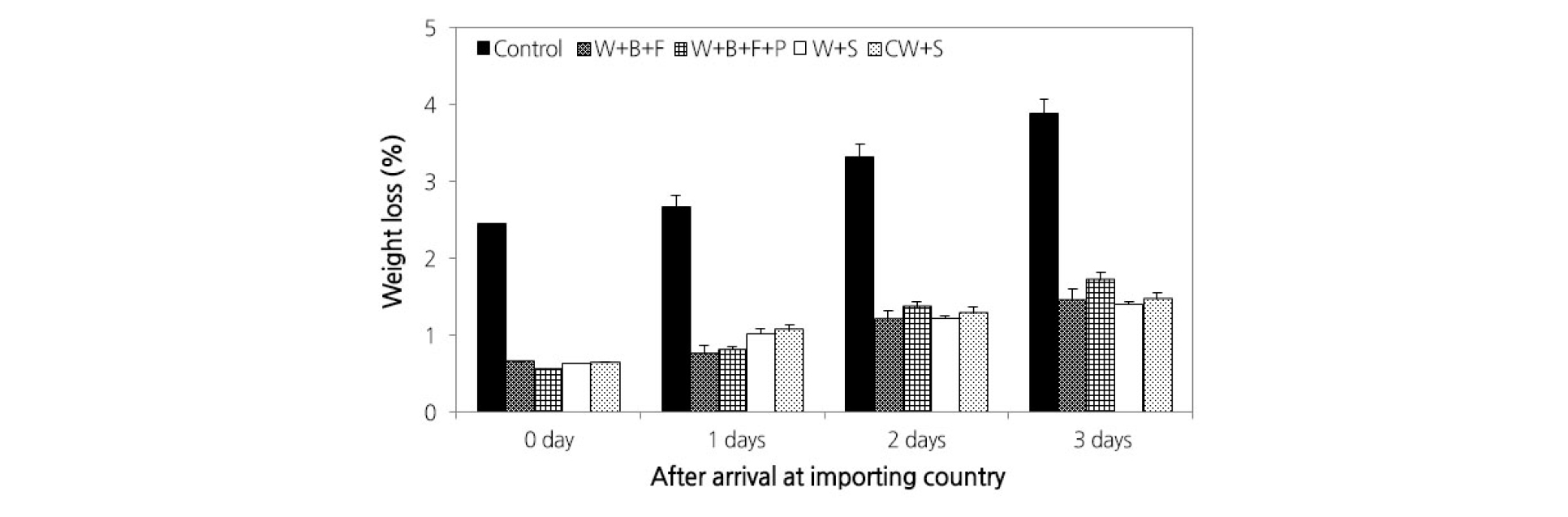

Harvested fruits and vegetables continue to respire and lose water to the environment, which cannot be replaced, resulting in weight loss (Thompson, 2003). Since weight loss equates to an economic loss, this quality parameter is crucial. Additionally, weight loss has a strong impact on the appearance of fruit due to shrinkage (Chang and Kim, 2015). The weight loss of the oriental melons under each treatment is shown in Fig. 3. Weight loss gradually increased during storage after arrival in Singapore in all treatments. The oriental melons in the control group (washing with water + corrugated box + PP film) showed the highest and fastest weight loss after arrival; up to 3.9% at 3 days after arrival. Weight loss was lower in the W+B+F, W+B+F+P, W+S, and CW+S treatments after arrival in Singapore. Increased weight loss may be associated with transpiration through microscopic cracks that form on the surface of fruits and vegetables (Hong and Kim, 2001; Kim et al., 2018). If the fruits and vegetables lose too much water through transpiration, turgidity is lost and the produce may appear slightly shriveled. The application of PE film and absorption paper in the corrugated box, and the small packaging treatment had a significant effect on reducing weight loss of melon fruits during distribution at 18°C in Singapore.

Fig. 3. Weight loss of oriental melon ‘Smartkkul’ by the various postharvest treatments during distribution at 18°C after arrival in Singapore. Control, washing + corrugated box + PP film; W+B+F, washing + corrugated box + PE film; W+B+F+P, washing + corrugated box + PE film + absorption paper; W+S, washing + small packaging; CW+S, washing by chitosan solution + small packaging. Vertical bars indicate ± standard errors.

Incidence of Surface Browning, Decay, and Marketability

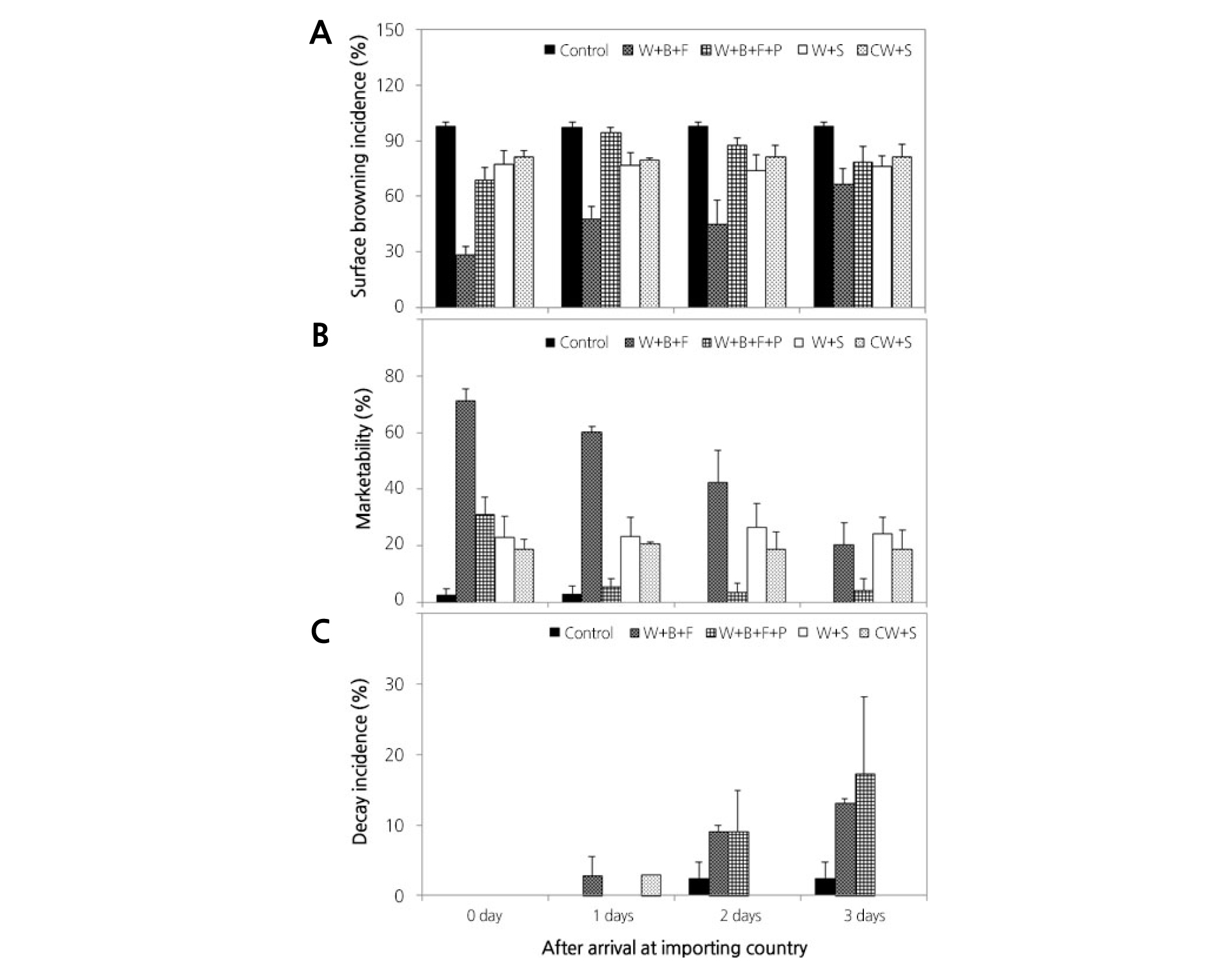

Browning is one of the main quality factors that can be affected during storage, and strongly affects the shelf life of fresh fruits and consumer purchase decisions (Oms-Oliu et al., 2010). The incidence of surface browning of oriental melon under each treatment after arrival in Singapore is shown in Fig. 4A. Surface browning occurs when the white part of the peel turns brown. After arrival in Singapore, surface browning of melons in the control group was the highest at 97.6%, whereas surface browning was the lowest in the W+B+F treatment at 28.6%. The PE film in the corrugated box was effective at reducing surface browning of melon fruit. There was no significant difference in washing treatment between the W+S and CW+S.

Fig. 4. Changes in surface browning (A), marketability (B), and decay (C) of oriental melon ‘Smartkkul’ by various postharvest treatments during distribution at 18°C after arrival in Singapore. Control, washing + corrugated box + PP film; W+B+F, washing + corrugated box + PE film; W+B+F+P, washing + corrugated box + PE film + absorption paper; W+S, washing + small packaging; CW+S, washing by chitosan solution + small packaging. Vertical bars indicate ± standard errors.

The marketability of oriental melon gradually decreased after arrival in Singapore (Fig. 4B). The marketability of the W+B+F-treated melon fruit was the highest at 71.4%. The control group, packaged in a corrugated box with PP film, had the lowest marketability at 2.4%, which was related to surface browning, and was no longer marketable 2 days after arrival in Singapore. In the small packaging treatments, the marketability ranged from 18.8-22.9% at 3 days after arrival in Singapore, and there was no difference in marketability between the two the small packaging treatments.

Fruit decay is one of the main causes of postharvest losses of horticultural produce (Choi et al., 2016a). The incidence of decay in the W+B+F+P treatment was 9.0-17.3% after arrival in Singapore.Both the W+S and CW+S treatments showed no decay on 3 days after arrival in Singapore (Fig. 4C).

Firmness

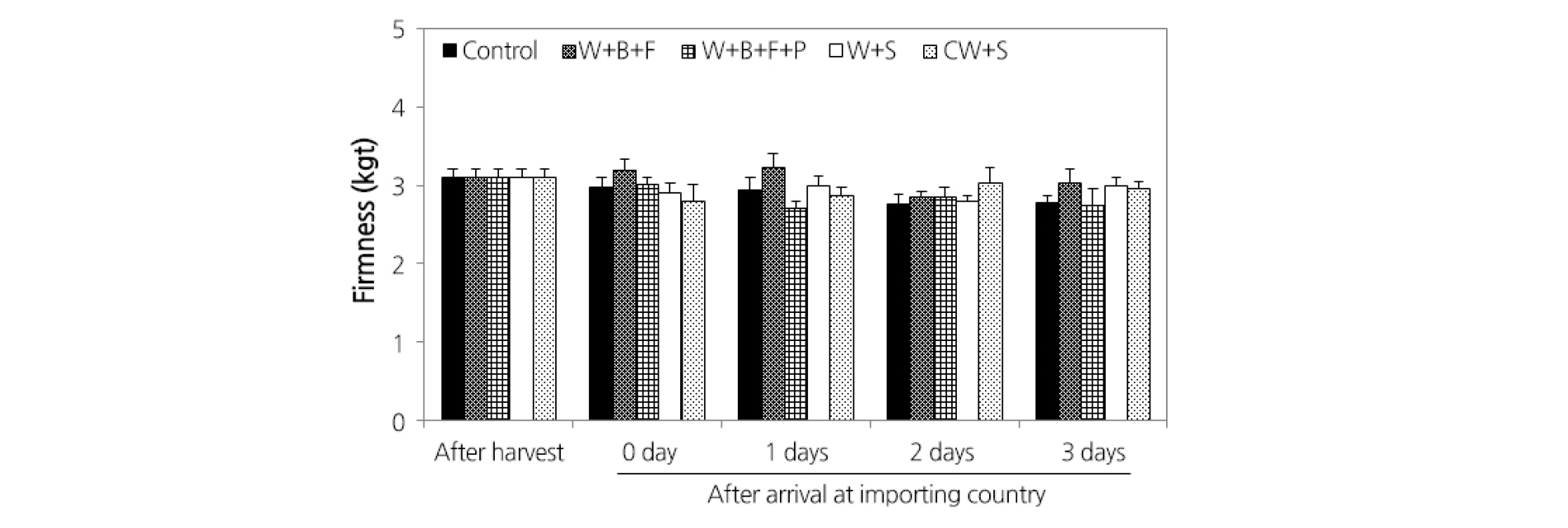

In general, the firmness of fruits and vegetables depends primarily on losses in turgidity, starch degradation, and chemical modifications in the cell wall (Rao et al., 2011). The firmness of the melon fruit averaged 3.1 kgf after harvest and was slightly decreased in all treatments after arrival in Singapore (Fig. 5). The firmness was lower in the small-packaged oriental melon than in the bulk-packaged melons after arrival. Overall, the firmness of W+B+F-treated melons was higher than in the other treatments after arrival. The CW+S treatment was more effective in maintaining firmness at 2 days after arrival, while firmness decreased in the control. Washing with chitosan prevented losses in firmness. This result is in agreement with Carvalho et al. (2016) who showed that firmness of chitosan-coated fresh-cut melon was maintained up to 20 days.

Fig. 5. Changes in firmness of oriental melon ‘Smartkkul’ by various postharvest treatments during distribution at 18°C after arrival in Singapore. Control, washing + corrugated box + PP film; W+B+F, washing + corrugated box + PE film; W+B+F+P, washing + corrugated box + PE film + absorption paper; W+S, washing + small packaging; CW+S, washing by chitosan solution + small packaging. Vertical bars indicate ± standard errors.

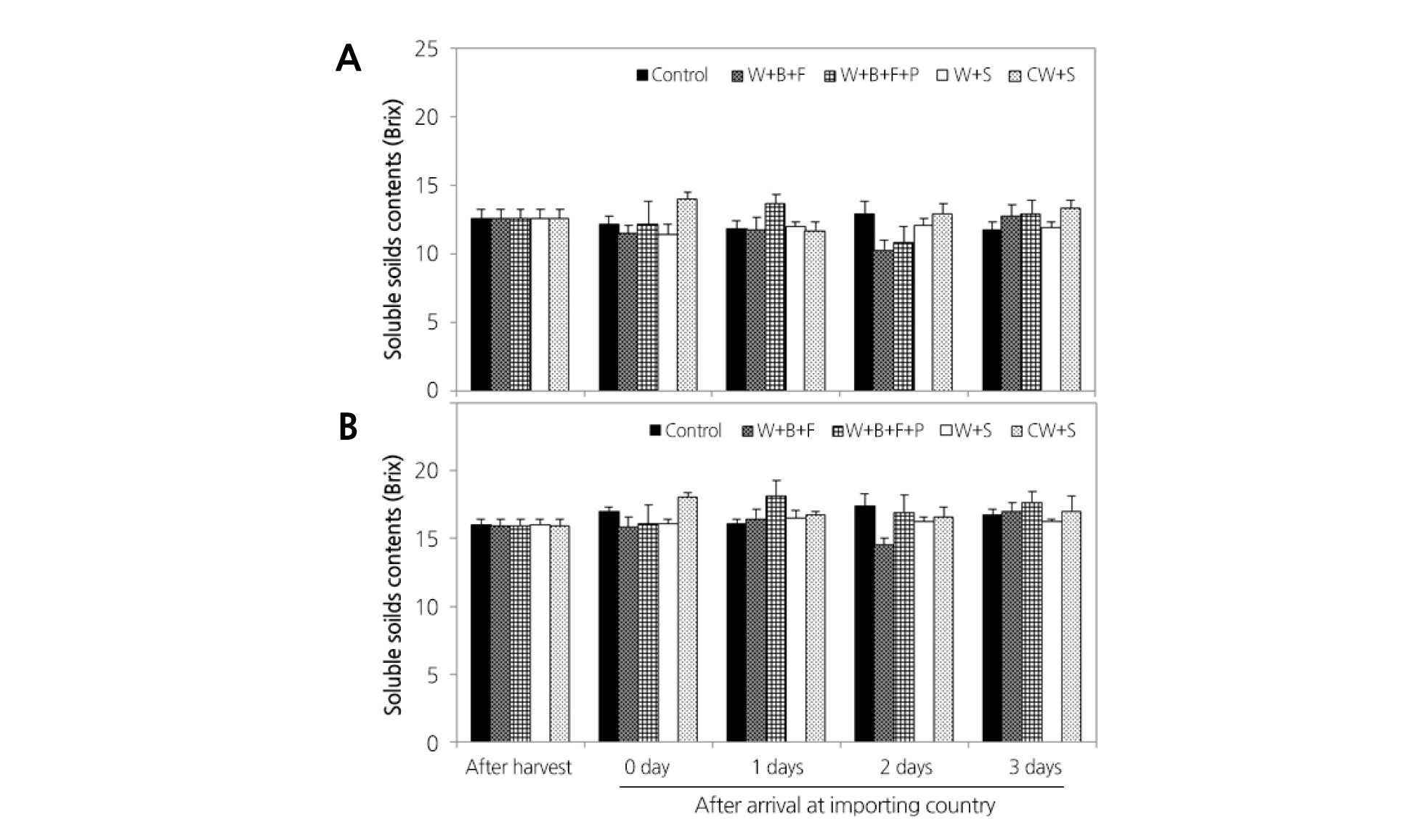

Soluble Solids Contents

The SSC is frequently evaluated because if its impact on sensory quality (Alsmeirat and El Assi, 2010). The SSC of oriental melon in each treatment is shown in Fig. 6. After harvest, the SSC of oriental melon flesh and seed averaged 12.6 and 16°Brix, respectively. After arrival in Singapore, the CW+S treatment resulted in a higher SSC than the W+S treatment (Fig. 6A). At 3 days after arrival, the SSC of melon flesh treated with CW+S was 13.3°Brix, whereas the SSC of the control was 11.7°Brix.

Similar results were observed for the SSC of the seed (Fig. 6B). The SSC of the seed increased after arrival in Singapore. Liu et al. (2012) reported that the SSC of oriental melon increased during storage, similar to the results of our study. Throughout the 3 days of distribution after arrival in Singapore, the SSC of the seed was higher than that of the flesh. The SSC of the melon seed in the W+B+F+P treatment was the highest at 17.7°Brix, whereas the SSC was the lowest at 16.3°Brix in the W+S treatment.

Fig. 6. Changes in soluble solids contents of oriental melon ‘Smartkkul’ flesh (A) and seed (B) by various postharvest treatments during distribution at 18°C after arrival in Singapore. Control, washing + corrugated box + PP film; W+B+F, washing + corrugated box + PE film; W+B+F+P, washing + corrugated box + PE film + absorption paper; W+S, washing + small packaging; CW+S, washing by chitosan solution + small packaging. Vertical bars indicate ± standard errors.

Marketability Evaluation

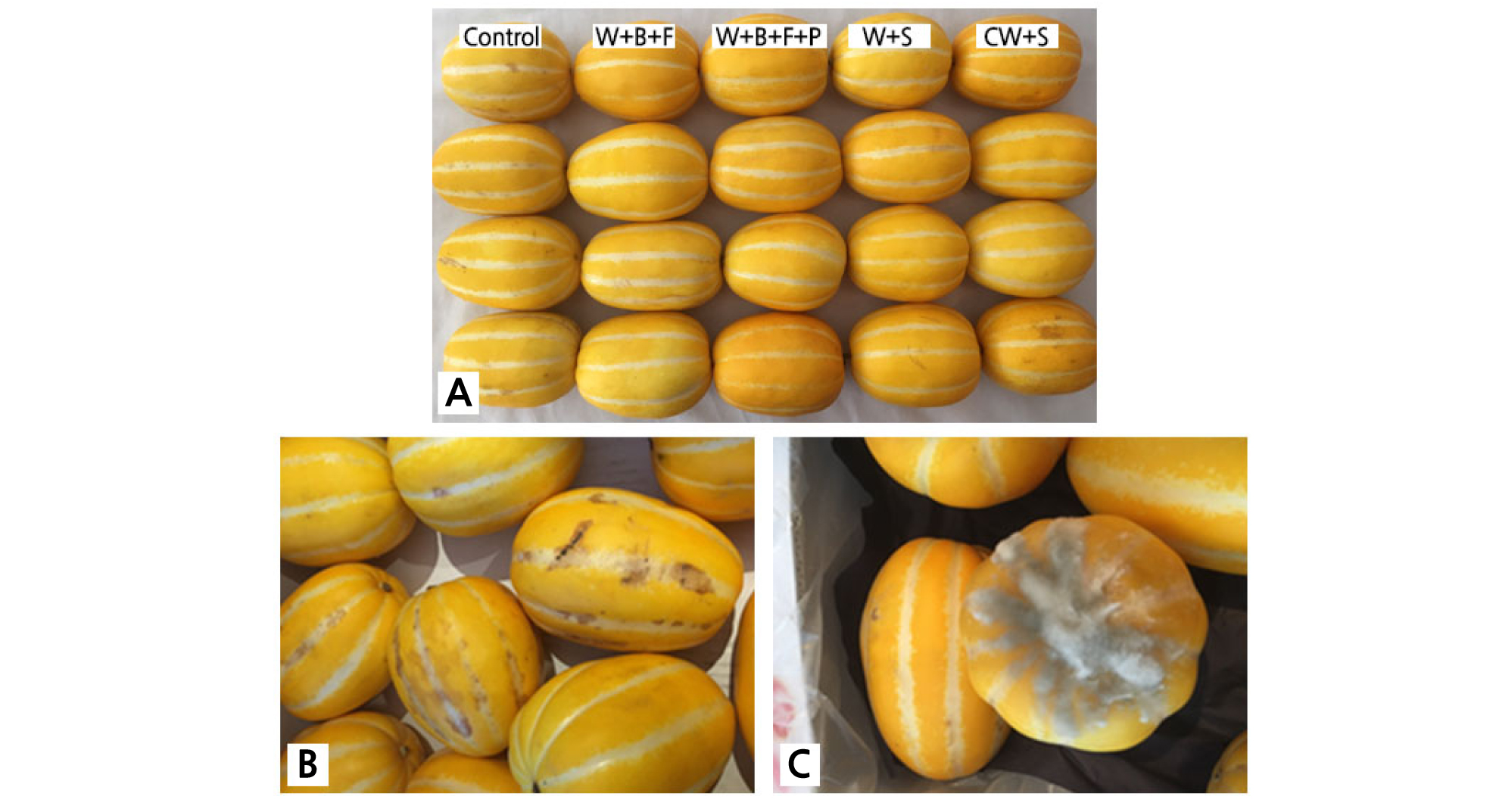

The fruit of oriental melon are usually purchased because of their large size, oval shape, good taste, and crispy texture (Yang et al., 2003). In this study, the melon fruit in the W+B+F treatment showed the best visual quality immediately after vessel export (Fig. 7A), while surface browning was observed in the other treatments (Fig. 7B), inferred by chilling injury and decay (Fig. 7C) during distribution.

Fig. 7. Appearance (A), surface defects and browning (B), and decay with grey mold (C) of oriental melon ‘Smartkkul’ after arrival in Singapore. Control, washing + corrugated box + PP film; W+B+F, washing + corrugated box + PE film; W+B+F+P, washing + corrugated box + PE film + absorption paper; W+S, washing + small packaging; CW+S, washing by chitosan solution + small packaging.

We interviewed local importers in Singapore on the marketability of oriental melon. Importers pointed out that the melon fruit had an attractive appearance; however, they had low sweetness and small size compared to local fruits. Also, the importers claimed that the oriental melon had low consumer preference due to a low SSC, because it is edible after removing the seed part like muskmelon.

This study suggests that the sale of oriental melon in Singapore should be complemented by differentiated marketing, such as excluding ‘melon’ in the name, as it has a lower SSC than other tropical fruits, and an emphasis on its functional components besides its attractive appearance. Because the SSC of the seed of melon fruit is higher than that of the flesh (Fig. 6), it is necessary to promote how to eat the oriental melon flesh and seed part together. The SSC of fruits produced and imported in the tropics is quite high due to the regional growing conditions. Therefore, distribution should be targeted to countries with cooler climates with fruits with low SSC such as Russia, Uzbekistan, and Mongolia.

Bulk packaging is effective to maintain the freshness of melon fruit and to reduce distribution cost, then grading and small packaging should occur on location after arrival importing country.