Introduction

To reduce petrochemical products, various studies have been carried out to analyze the economic value of biodegradable seedlings (Hall et al., 2012; Susmitha et al., 2015) and investigate the role of paper sludge seedlings (Song et al., 2010; Lee et al., 2014; Nandede et al., 2014). Cylindrical paper pots (CPPs) as eco-friendly biodegradable seedling pots introduced in Korea in 2014 and are currently being used in more than 10 geographic locations (Seo et al., 2017). The difference between a conventional plug tray system (Plug) and a CPP system lies in the type of substrate support for root zone environment. In the Plug system, a tray is filled with soil to create a physical environment. However, the CPP system is not supported by a plastic tray. It can maintain its physical shape because the soil is wrapped with paper. Thus, the tray only facilitates mounting of finished CPP seedlings. The CPP system, unlike the Plug system, can create gaps between root surfaces of seedlings and the plastic tray surface.

Due to gaps between the root surfaces and the plastic tray surface, the CPP system not only ensures excellent air permeability and air pruning effect, but also facilitates extraction of seedlings to minimize root fracture during formalization (Kumar Prasanna and Raheman, 2011). In addition, it is not necessary to wait for roots of seedlings to cover the soil substantially to reduce production rate of old seedlings (Kim et al., 2018; Seo et al., 2018).

Most CPP studies have been conducted on air pruning effect (Maguire and Harun, 2007; Edward et al., 2012; John, 2013; Ryan et al., 2018), establishment of quality seedling standard using Dickson Quality Index (DQI) and Relative Growth Ratio (RGR) (Seo et al., 2018), or localization of manufacturing equipment (Park et al., 2017). Most of previous CPP studies were focused on trees (Michael and Edward, 1998; Shiman, 2013; Darby et al., 2017). Studies involving fruits and vegetables using CPP have been reported only recently (Seo et al., 2017; Jang et al., 2018; Kim et al., 2018).

Irrigation strategies for seedlings should be based on seedling type, characteristics, and growth stage. Most of previous studies investigating moisture management of conventional seedlings were conducted using the Plug system or the flowerpot cultivation system (Shim et al., 2018; Ndikumana et al., 2019). Although Lucas et al. (2018) have conducted irrigation studies using cylindrical paper pots, their study is on trees.

CPPs and plug trays are similar in appearance. However, they work under different physical environments as described above (Seo et al., 2018). Conventional methods used for plug seedlings are not recommended for CPP seedlings. Instead, water content management at the root zone is essential for CPP seedlings due to difference in breathability between CPP and plug trays.

The CPP and existing plug systems for seedlings are not significantly different in price. However, CPP is preferred by seedling companies and farmers to formalize machinery and manpower (Seo et al., 2017). Although domestic seedling companies have introduced new seedling systems, most farms still apply the current standards of conventional irrigation generally based on experiences of experts rather than a quantified automatic supply system. As such, watering deviations are more likely to occur depending on the manager’s career and environment. For beginners, challenges such as uneven watering can occur easily. For this reason, it is important to establish irrigation management standards suitable for CPP seedlings.

The objective of this study was to examine responses of cucumber and watermelon to excessive water stress after grafted seedlings were grown in Plug or CPP system. Results of this study could be used to establish watering management standards for the production of high quality CPP seedlings.

Materials and Methods

This experiment was performed from February 7, 2018 to May 9, 2018 at the Greenhouse of Kangwon National University in Chuncheon, Gangwon-do, Korea. Test crops included cucumbers and watermelons. Cucumber ‘Joeun (Heungnong. Co., Ltd, Korea)’ was grafted to stock ‘Huckjong (Heungnong. Co., Ltd, Korea)’. Watermelon ‘Joeunggual (Heungnong. Co., Ltd, Korea)’ was grafted onto stock ‘Bulrojangseng (Syngenta korea. Co., Ltd, Korea)’. Both crops were sown on a 128-cell plug tray (Bumnong. Co., Ltd, Korea) on February 7, 2018 (cucumber) or March 12, 2018 (watermelon). Seedlings of stock were wrapped in ‘Pindstrup’ (EC 0.47 dS·m-1, pH 6.18, PINDSTRUP, Denmark) with a biodegradable paper (trade name: ‘Hydroponics’, Ellegaard, Denmark) [40-cell, volume per cell: 60 cc (ø 39 mm x height 39 mm)] and grown in a CPP with a 40-cell tray (Bumnong Co., Ltd, Korea). In the Plug system, 40-cell trays were filled with the same volume (60 cc in each cell) of the clay used for the CPP.

After sowing, they were transferred to a germination room at a temperature of 28°C and humidity of 90% for two days. Seedings were grown for 12 days in a seedling greenhouse. On February 21, 2018 (cucumber) and March 26, 2018 (watermelon), seedlings were grafted on CPPs and Plugs followed by recovery for 5 days in the rooting room. They were then grown in the nursery greenhouse for the second time. During the seedling period, the seedling greenhouse environment was maintained at an average temperature of 17 ‑ 20°C (the lowest temperature: 16°C; the highest temperature: 26°C) for 24 hours.

Irrigation treatments were conducted for 20 days starting from March 6th (cucumber) or April 17th, 2018 (watermelon). A one-time irrigation was performed using an overhead irrigation system: 300 mL (treatment 1) for the control, 450 mL (treatment 2) for the plug tray, and 600 mL (treatment 3) for the CPP system.

The frequency of irrigation was adjusted according to the quantity of light and weather (about 2 ‑ 3 times on sunny days, and 0 ‑ 1 time on cloudy days). Fertilization was carried out with two-phase watering twice a week using seedling fertilizer ‘Herbal’ (Coseal, Korea) with an EC concentration of 1.2 ‑ 1.5 dS·m-1. A total of six experimental plots (each divided into three) were used.

Seedling growth was measured every five days after irrigation treatment. Five plants were collected from each experimental plot. The height was defined as the length from the branch to the top. Stem diameter was measured using a digital caliper. It was found to be 1 cm above the graft. The leaf area was measured with a leaf area meter (LI-3100, Area meter, LI-COR Inc., USA). Root growth was investigated after soaking the paper pot and soil for 1 hour, followed by immersion of the root in alcohol solution (30% isopropanol) and storage in a refrigerator (4°C) (Böhm, 1979; Kücke et al, 1995). Total root length, root diameter, root tip number, and total root area were examined using a WinRHIZO program (WinRHIZO PRO 09, Regent Instruments Inc., Canada). Root length and thickness were analyzed in five stages (0.05 mm or less, 0.05 ‑ 0.1 mm, 0.1 ‑ 0.15 mm, 0.15 ‑ 0.2 mm, and 0.2 mm or more). After washing plant roots, fresh weight was measured after separating leaves, stems, and roots using an electronic balance. Dry weight was measured after drying for 48 hours at 70°C in a dryer (Shellab-1501).

In addition, leaf dry weight ratio (LWR; Eq. 1), stem dry weight ratio (SWR; Eq. 2), root dry weight ratio (RWR; Eq. 3), T/R ratio (Eq. 4), Compactness (Eq. 5) and Dickson Quality Index (DQI; Eq. 6) were calculated as following equations (Dickson et al., 1960).

| $$LWR(g\cdot g^{-1})=\frac{Leaf\;dry\;weight}{Total\;dry\;weight}$$ | (1) |

| $$SWR(g\cdot g^{-1})=\frac{Stem\;dry\;weight}{Total\;dry\;weight}$$ | (2) |

| $$RWR(g\cdot g^{-1})=\frac{Root\;dry\;weight}{Total\;dry\;weight}$$ | (3) |

| $$T/R\;ratio=\frac{Top(leaf+stem)\;dry\;weight}{Total\;dry\;weight}$$ | (4) |

| $$Compectness(mg\cdot cm^{-1})=\frac{Top(leaf+stem)dry\;weight}{Plant\;height}$$ | (5) |

| $$DQI=\frac{Total\;dry\;weight}{\frac{Height}{Stem\;diameter}+\frac{Top\;dry\;weight}{Root\;Dry\;weight}}$$ | (6) |

Quantitative values measured in this experiment were expressed as the mean and standard error using SPSS program (Ver. 24, IBM, USA). Statistical significance of each test was tested at 5% level using analysis of variance (ANOVA) and F-test.

Results and Discussion

Results of shoot growth in CPP and Plug systems based on moisture stress are summarized in Table 1. For the growth of cucumber in CPP and Plug systems, the leaf area was decreased by 13% and 17%, respectively, as the volume of irrigation water was increased, consistent with previous reports of diminished leaf area following excessive moisture treatment (Choi et al., 1997; Yoon et al., 2001). However, this result is different from results of Park and Jeong (2003). They reported that the leaf area index was increased by 32 ‑ 45% as the irrigation water volume increased during tomato plug seedling. In the present study, the average value of TRR in the CPP system was 18% higher than that in the Plug system. In both systems, the TRR tended to decrease with increasing irrigation water volume. The average diameter was 4.53 mm in the CPP system and 4.41 mm in the Plug system, consistent with previous studies showing increased thickness of tomato plug seedlings with increasing irrigation (Park and Jeong, 2003; Kim et al., 2018). CP ranged from 36.89 to 42.31 mg/cm in the CPP system and 38.28 to 42.53 mg/cm in the Plug system, consistent with previous results showing increase in CP as irrigation volume increased under CPP system for pine seedlings (Lucas et al., 2018). However, it differed from results of Kim et al. (2018) showing that the CP of tomato plug seedlings decreased with increasing irrigation volume. These results might be attributed to different physicochemical properties of artificial substrate used in each experiment. The DQI value was used as a quality indicator of tree seedlings (Dickson et al., 1960). It was analyzed by Seo et al. (2018) as an indicator of the quality of CPP seedlings. DQI values of CPP irrigation stage 3 and Plug irrigation stage 2 were the highest at 0.063 and 0.064, respectively. The average value of LWR indicating dry weight distribution of leaves was 6.4% higher in the Plug system than that in the CPP system. The SWR in the Plug system was 3.4% higher than that in the CPP system, suggesting that CPP could distribute dry weight by leaves rather than by stems. However, the Plug system distributes dry weight by stem. In this regard, further studies are needed to obtain more accurate results.

Table 1. Shoot growth characteristics of cucumber and watermelon seedlings in cylindrical paper pot trays (CPP) or plug trays (Plug) according to irrigation treatment

xSWR = shoot dry weight / total dry weight.

wDifferent letters within columns indicate the mean separation by Duncan's multiple rage test (p = 0.05).

vNS, *, **, ***; significant at p ≤ 0.05, 0.01, and 0.0001, respectively.

Regarding growth of watermelon, the average leaf area in the CPP system was 18% higher than that in the Plug system. In addition, both systems involved three stages of irrigation at 280.7 cm2 and 230.5 cm2, respectively. As the irrigation water volume increased, the leaf area decreased significantly. The average value of TRR in the CPP system was 27.2% larger than that in the Plug system. In irrigation treatment 1, CPP (18.83) and Plug (15.56) had the highest TR rates.

Conversely, stem diameters in both CPP and Plug systems tended to be thicker with increasing irrigation water volume. A similar tendency was also observed for CP. Neither stem diameter nor CP showed significant differences between the two seedling systems. However, the CP value depending on the irrigation volume DQI was 0.006 higher in the CPP system than that in the Plug system. It increased as the amount of irrigation increased. The LWR in the CPP system was 0.03 larger than that in the Plug system. In both systems, the LWR tended to increase significantly as the level of irrigation decreased. The SWR in the Plug system was 0.02 larger than that in the CPP system. In both systems, the SWR tended to increase with higher irrigation volume, although the increase was not statistically significant. The above-ground growth was higher in the CPP system than that in the Plug system. In addition, as the amount of water in both CPP and Plug systems increased, total growth decreased, although seedling growth tended to be thick and hard (Kim et al., 2005). Lucas et al. (2018) have reported higher plant height (52%), larger stem diameter (21%), more shoot dry weight (86%), and more total fresh weight (62%) when the irrigation water volume of Brazilian pepper seedlings in CPP is larger. Their results are inconsistent with results of the present study which showed smaller the growth with larger irrigation water volume. Such inconsistency might be attributed to differences in criteria for appropriate irrigation levels required for trees and vegetables as well as differences in the degree of water stress. These results need to be verified with further studies.

Table 2 presents results of root growth in cucumber and watermelon grafted seedlings subjected to excessive watering. The total root in the Plug system was 18% longer than in the CPP system. The lowest irrigation volume’s total root lengths were 1031.1 cm (CPP) and 1143.1 cm (Plug), which was 22% (CPP) and 16% (Plug) longer than largest irrigation volume’s total root length. Therefore, in both CPP and Plug systems, total root length decreased as irrigation water volume increased. These results are consistent with results of Jang et al. (2018) reporting that root length of watermelon seedling grown in the Plug system is longer than that grown in the CPP system. Darby et al. (2017) have reported that the root length of seedling grown in CPP is decreased when aerial pruning effect is increased due to the effect of increased root rotation without air pruning when the tip of the root touchs the plastic tray (Whitcomb, 1985). Root diameters were divided into five stages ranging from 0.05 mm to 2.0 mm or more. Both systems measured less than 0.05 mm, 0.05 ‑ 1.0 mm, 1.0 ‑ 1.5 mm, 1.5 ‑ 2.0 mm and more than 2.0 mm at 72%, 20%, 5%, 2% and 1%, respectively (data not shown). In particular, the proportion of rootlets less than 0.05 mm in the Plug system was 3% higher than that in the CPP system, consistent with results of Jang et al. (2018), suggesting that the Plug system was a better development system for the rootlet than the CPP system. The average root surface area in the Plug system was 10% wider than that in the CPP system, although the difference was not statistically significant. This finding was consistent with the study of Darby et al. (2017) showing that the root surface area per unit volume was not affected by the type of tray in tree seedlings. In addition, the surface area tended to be larger with lower irrigation volume in both systems. These results were consistent with results of Cha et al. (2017) reporting that there was no significant difference in surface area even if the irrigation volume increased as long as the frequency of irrigation was less than three times during pine seedlings. At root level, both systems showed decreases when the irrigation amount was excessive, similar to results of Cha et al. (2017) reporting that the dry weight in the rhizosphere increased as the amount of irrigation during pine seedlings increased. However, it decreased slightly when the amount of irrigation exceeded a certain level probably due to the lack of breathability caused by excessive moisture in the soil rhizosphere (Choi et al., 1997). The RWR represents dry matter distribution of roots. Average RWR in the Plug system was 25% larger than that in the CPP system. In both systems, RWR tended to increase with higher irrigation volume. Based on results shown in Table 1, stress response due to excessive moisture was relatively smaller in the rhizosphere than that in the shoot. In this regard, further experiments are needed. In the rhizosphere of watermelon, total root length in the Plug system has been found to be 14% higher than that in the CPP system (Jang et al., 2018). The total root length in the CPP system was 449.5 cm during the three stages of irrigation. The Plug system carried the longest root at 559.8 cm during the second irrigation phase. The root surface area in the Plug system was larger than that in the CPP system. CPP had the third stage of irrigation and the second stage of plug.

Table 2. Root length (in five types), average root diameter, root surface, root dry weight and RWR of cucumber and watermelon seedlings cylindrical paper pot trays (CPP) and plug trays (Plug) according to irrigation treatment

yRWR = root dry weight / total dry weight

xDifferent letters within columns indicate the mean separation by Duncan's multiple rage test (p = 0.05).

wNS, *, **, ***; significant at p ≤ 0.05, 0.01, and 0.0001, respectively.

RWR was also higher in the Plug system than that in the CPP system. It tended to increase with increasing levels of irrigation in both systems. Taken together, these results of root growth suggest that higher soil water content can result in greater inhibition of rhizosphere development because Plug does not exhibit air pruning effect. It can induce root rotation, which can lead to large-scale distribution of roots at the bottom. However, CPP can lead to short length roots due to its air pruning effects (John, 2013).

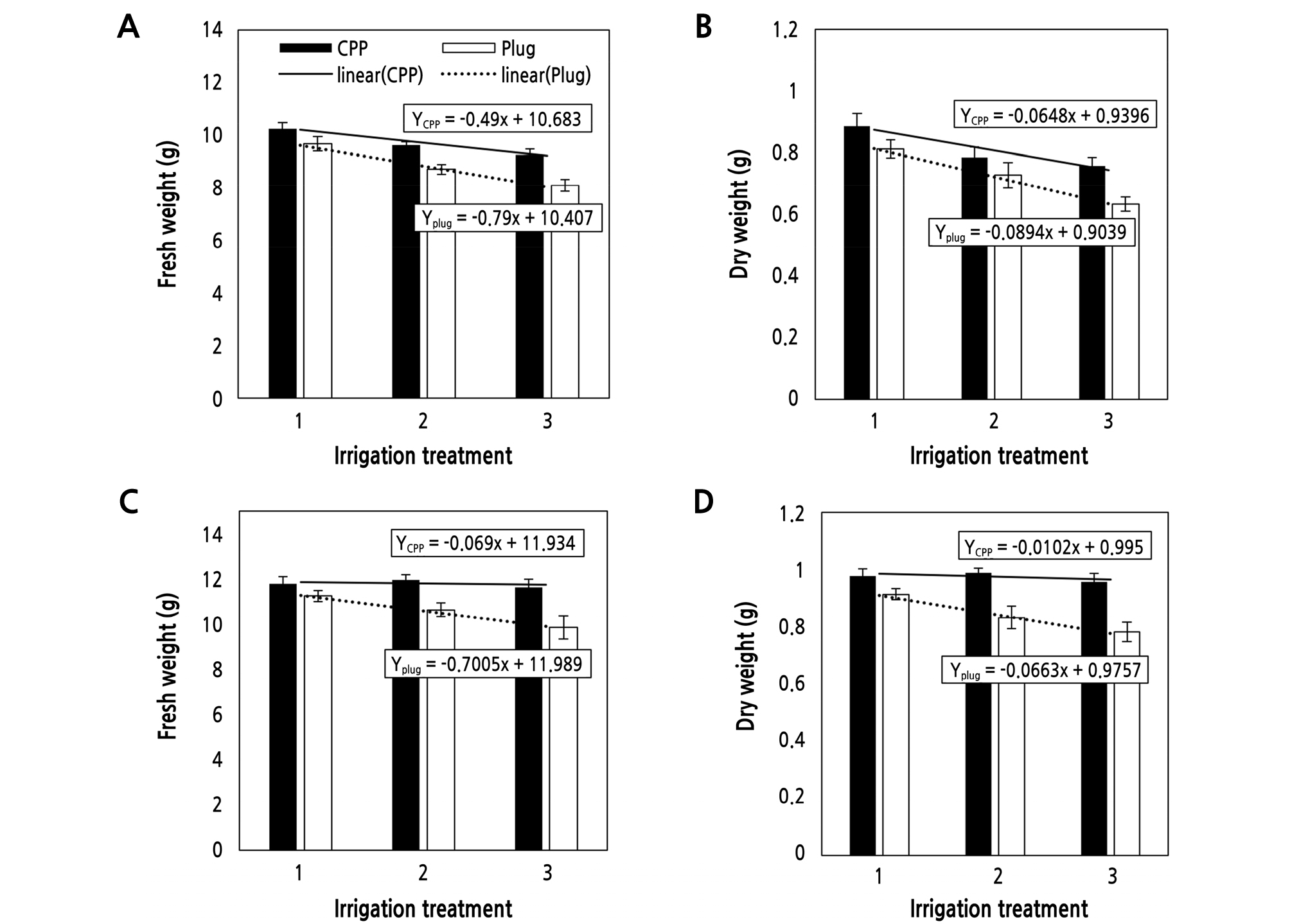

To compare the extent of growth reduction due to excessive moisture between the two seedling systems, fresh and dry weights of seedlings at the time of planting were investigated. Results are shown in Fig. 1 and Table 1. In the third stage of irrigation of cucumber-grafted seedlings, the fresh weight was 9.25 mg in the CPP system and 8.11 mg in the Plug system (0.98 mg and 1.58 mg less than in the first stage of irrigation, respectively). After three stages of irrigation, the dry weight was 0.75 g in the CPP system and 0.63 g in the Plug system (0.13 g and 0.18 g less than in the first stage of irrigation). Therefore, in both CPP and Plug systems, fresh and dry weights tended to decrease with increasing irrigation volume (Table 1). Fresh weights of cucumber-grafted seedlings in CPP and Plug systems were ‑0.49 and ‑0.79, respectively. Seedlings in the Plug system showed 61% lower weight than seedling in the CPP system. The slope of the trend line in dry weight was ‑0.08 for the Plug system and ‑0.06 for the CPP system (a reduction of 38% compared to the Plug system). As such, CPP system resulted in less growth than the Plug system. This might be attributed to the effect of moisture in the root zone due to difference in breathability (Seo et al., 2017). The slope of watermelon grafting in the CPP system tended to decrease to ‑0.06 for fresh weight and ‑0.01 for dry weight, whereas that in the Plug system tended to decrease to ‑0.70 for fresh weight and ‑0.06 for dry weight.

Thus, watermelon-grafted seedlings showed a decrease in growth with increasing volume of irrigation water, indicating aerobic growth of rhizosphere in watermelon. With the CPP system which was well ventilated, watermelon seedlings did not lose growth. However, their growth might have been influenced by the lack of breathability in the Plug system.

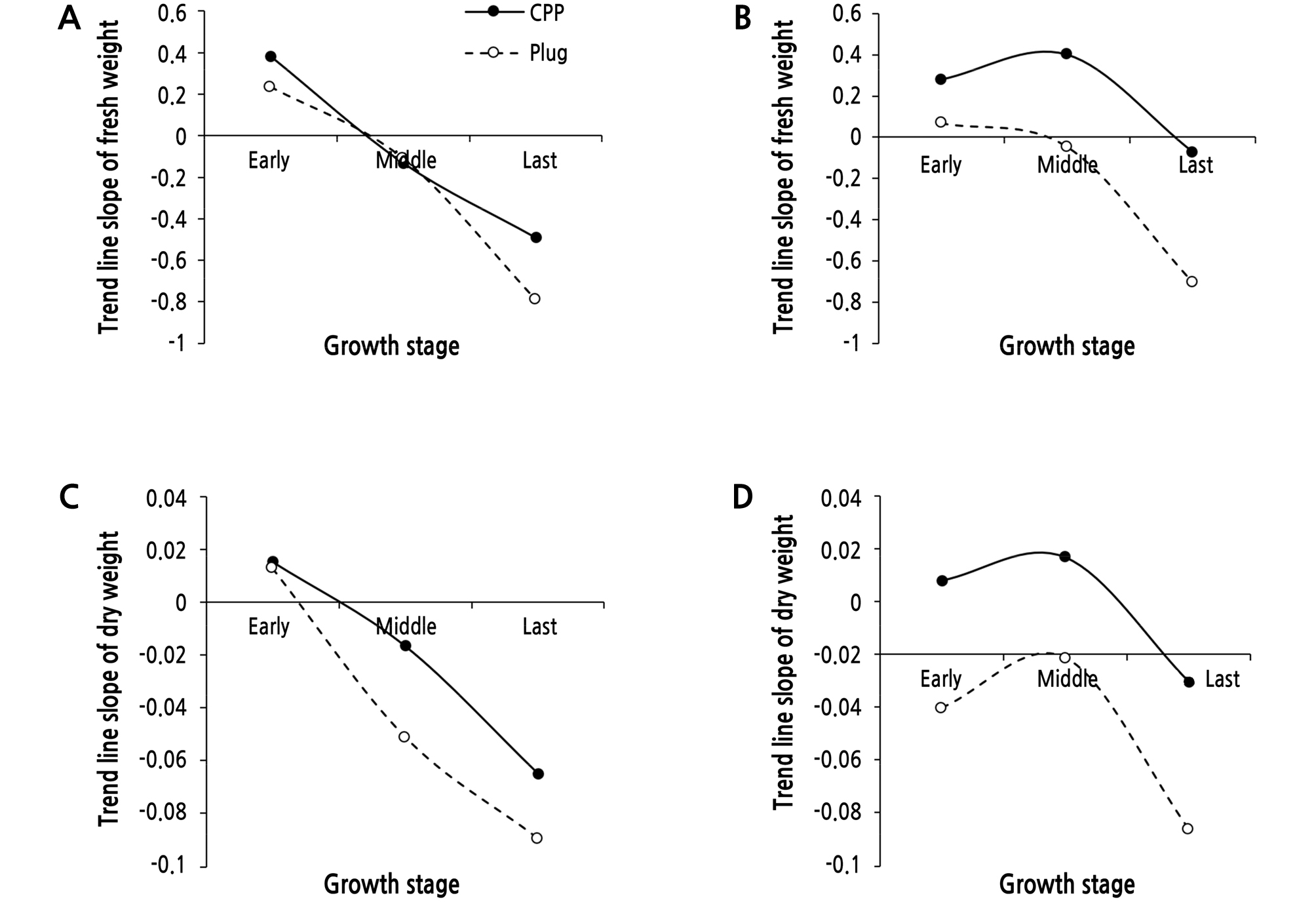

Trend lines analyzing the growth of cucumber and watermelon seedlings (Fig. 1) are shown in Fig. 2 for different growth stages. The slope of fresh weight of cucumber was +0.2 ‑ +0.4 in both CPP and Plug systems at the beginning of growth. However, from the mid-growth period, it showed a tendency to decrease slightly (0 ~ ‑ 0.1). In the last stage of growth, it showed a tendency to decrease substantially in both Plug and CPP systems as irrigation volume increased. The slope of cucumber dry weight was similar to that of fresh weight. However, it decreased more in the Plug system than in the CPP system. The slope of fresh weight of watermelon was +0.3 ‑ +0.4 until the mid-growth in the CPP system. As irrigation volume increased, its growth also tended to increase. It showed no significant difference at the last stage of growth.

Initially, the growth in the Plug system showed a tendency to increase slightly as the irrigation volume increased. However, there was no difference in middle stage of growth. In the last stage of growth, the growth rate was ‑0.8, indicating that the growth was diminished with higher irrigation volume. Dry weight results of watermelon were similar to fresh weight results in the CPP system. Growth in the Plug system tended to decrease as irrigation volume increased to ‑0.02 and ‑0.08. However, there was no significant difference in the test period in the middle of growth.

In summary, seedling growth tended to decrease in the presence of increased water levels in both CPP and Plug systems (Tables 1 and 2), although the decrease was greater in the Plug system than that in the CPP system (Fig. 1). The decrease in growth did not appear in early stages. It was apparent only in the middle stage. It was more severe as growth progressed (Fig. 2). Initially, substantial irrigation in both CPP and Plug systems facilitated seedling growth. However, the growth was suppressed after reaching a certain level. The effect of irrigation on growth in the CPP system was relatively less than that in the Plug system. This suggests that the CPP system can be used to reduce damage caused by excessive water content of the substrate. This difference is caused by the gap between the tray and the paper pot, which is inherent to CPP. This gap can increase the amount of supply water lost during over-head irrigation, reducing the amount absorbed by the rhizosphere. In addition, the large exposed area can enhance the transpiration rate in the rhizosphere.

Because seedling companies and small-scale farmers manually water plants instead of using automated watering equipment, problems associated with excessive watering often occur. However, the use of CPP system can mitigate such problems. Therefore, the CPP system is expected to stabilize management by increasing income and reducing labor cost. However, practical implementation of CPP system requires a comprehensive evaluation of various crops and irrigation levels. Follow-up studies investigating effects of CPP system on the growth after formalization are needed.